138 kV Disconnect Switches: Essential Components for Power System Safety and Flexibility

In high-voltage transmission and substation infrastructure, the 138 kV disconnect switch (commonly known as an isolator) is a fundamental component. Operating at a critical transmission voltage, these robust devices provide vital safety and operational functions distinct from circuit breakers.

Core Function: Visible Isolation

The primary purpose of a 138 kV disconnect switch is to establish visible physical isolation through an air gap. When fully open, the separated blades create a clear break in the circuit. This isolates specific equipment—transformers, bus sections, lines, or circuit breakers—from live sections elsewhere. This isolation serves two critical purposes:

I. Personnel Safety: Provides a verifiable de-energized state for maintenance, inspection, or repair work downstream. The visible gap offers essential safety confirmation beyond relying solely on relay indicators or control systems.

II. Operational Flexibility: Enables network reconfiguration for load transfers, sectionalizing during faults, or routing power through alternative paths without de-energizing entire substations.

Operational Characteristics and Design

Voltage Rating: Designed for 138 kV systems with rigorous dielectric withstand capabilities for power frequency and impulse voltages.

Current Rating: Engineered to carry maximum continuous load current without exceeding temperature limits and withstand specified short-circuit currents for defined durations (e.g., 3 seconds).

Switching Limitation: Standard disconnect switches cannot interrupt load or fault current. Operating under load creates destructive arcs. They function only after an upstream circuit breaker has de-energized the circuit.

Specialized Interruption: Some designs incorporate arcing horns or chambers to interrupt minimal charging currents (e.g., unloaded bus sections) or controlled loop currents, as defined by manufacturers and standards (IEEE C37.30, IEC 62271-102).

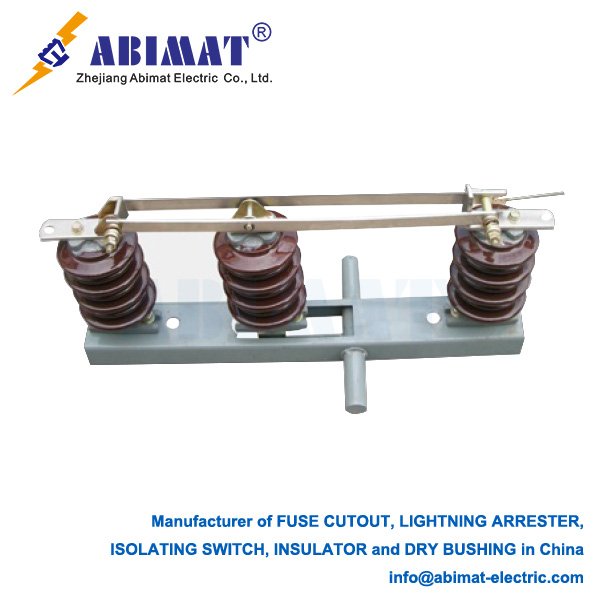

Mechanical Design: Built for reliability and longevity in outdoor environments. Common configurations include:

Center-Break: Horizontally rotating insulators move a central blade.

Vertical-Break (Single/Double): Blades pivot vertically, offering compact footprints and better ice-shedding capability.

Pantograph: Scissor-like mechanism for vertical reach, ideal for bus transfers.

Operation: Manual (via insulated rods/cranks) or motorized actuators (for remote/SCADA integration).

Critical Safety Systems

Interlocks: Mandatory mechanical/electrical locks prevent unsafe operations, primarily blocking disconnect switch opening while its associated circuit breaker is closed. Additional interlocks may restrict access to live compartments.

Grounding Switches: Often integral or directly associated. These provide a visible means to safely ground the isolated section before work begins, protecting personnel from induced voltages or accidental re-energization. Interlocks prevent simultaneous closure of disconnect and grounding switches.

Selection Criteria

Selection requires careful assessment of:

Continuous Current Rating

Short-Time Withstand Current (kA) and Duration

Rated Voltage and Dielectric Strength (BIL)

Switching Capability (if applicable: capacitive, loop)

Environmental Conditions (wind, ice, seismic, pollution)

Configuration Type (center-break, vertical-break, pantograph)

Control Method (manual, motorized)

Compliance with IEEE C37 series or IEC 62271 standards.

Maintenance Imperative

Routine inspection and maintenance ensure long-term reliability:

Verify blade alignment and contact pressure

Ensure smooth mechanism operation

Inspect insulators for damage/contamination

Test interlocks

Maintain proper lubrication

Conclusion

The ABIMAT 138 kV disconnect switch is a critical element for power system safety and flexibility. By providing unambiguous physical isolation and enabling safe work practices through visible gaps and grounding, it protects personnel and supports reliable transmission network operation. Its robust construction ensures decades of performance under demanding electrical and environmental conditions.