Fuse Cut-Outs: Essential Protection for 20kV Distribution Networks

Fuse cut-outs provide critical overcurrent protection in 20kV overhead distribution systems. These field-proven devices combine fault interruption with visible isolation, safeguarding transformers, feeders, and cables against persistent overloads and short-circuit damage.

Operational Principle

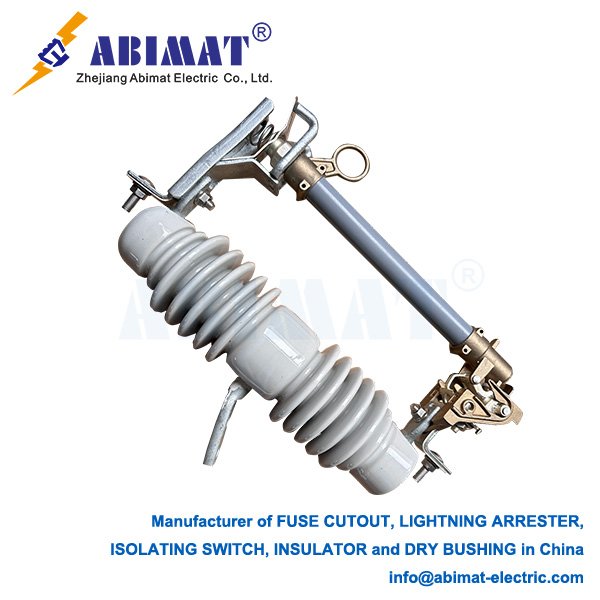

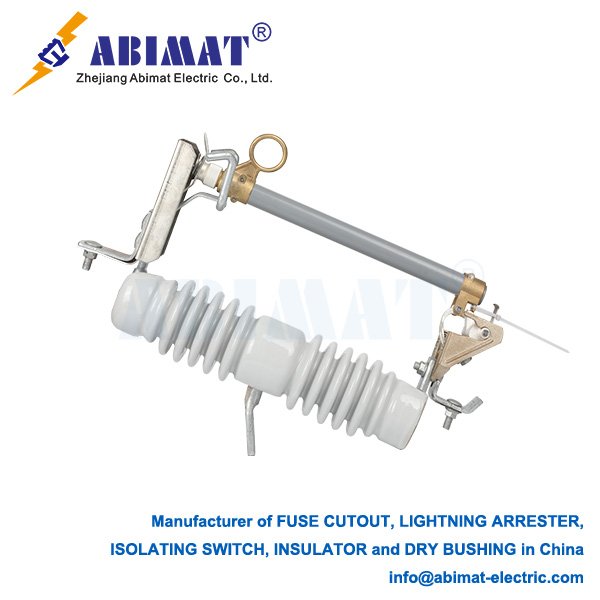

A standard cut-out features three integrated components:

I. A polymer or porcelain insulator providing structural support and electrical isolation

II. A pivoting fuse carrier housing the current-limiting fuse element

III. A contact assembly with precision-engineered latch/release mechanics

Fuse cut-outs are key safety tools on those big 20,000-volt power lines up in the air. They guard things like transformers and cables. They stop them from getting ruined when there’s a dangerous power surge or an electrical short. People trust these devices for a reason. They don’t just stop the problem—they also make it obvious when they’ve done their job.

Technical Specs

Voltage: Works with 20kV lines, up to 24kV at most.

Current it can handle nonstop: 100A, 200A, or 300A.

How much power it can shut off: At least 12.5kA (follows IEC 60282-1 rules).

Shock resistance: Can take 125kV jolts.

Fuse types: Fast-acting (K/T-type) or slower (S-type)—they respond to current over time differently.

Creepage: Needs to be 400mm or more for areas with medium pollution (check IEC 60815).

Main Jobs

It clears problems downstream fast—within 0.5 to 5 cycles.

It keeps outages small, only hitting the part that’s affected.

You can see when it’s cut the power—there’s a physical sign.

It lets workers switch transformers by hand, using insulated sticks.

It limits how big a fault gets, thanks to the fuse acting quick.

What Makes Them Better

They clear transformer problems three times faster than reclosers.

They cost 40 to 60% less than circuit switchers—easy on the budget.

You can swap out the fuse links right in the field. Downtime? Less than five minutes.

Gravity helps them work, so they always disconnect safely if something goes wrong.

They fit right in with surge arresters and fault indicators—no extra hassle.

Where They Go to Work

They protect transformers, the ones from 50kVA up to 2.5MVA, on the main side.

On radial circuits, you’ll find them every 3 to 5 poles, splitting the feeder into sections.

They stop capacitor banks from failing one after another when there’s a short circuit.

They’re good for critical spots: industrial power lines, mining setups, coastal networks.

Selection and Maintenance

– Fuse rating must withstand transformer inrush (12× nominal for 0.1s)

– Interrupting capacity exceeding available fault current

– UV-stabilized EPDM seals for polymer housings

– IEC 61936-compliant creepage for polluted environments

Maintenance Protocol:

I. Annual infrared scanning of contact points

II. Verification of carrier drop angle (≥90° from horizontal)

III. Dry-period insulator cleaning

IV. Fuse replacement after two operations

V. Operational testing with load-break tools

Standards Conformance

– IEC 60282-1 (High-voltage fuses)

– ANSI C37.41 (Distribution cutouts)

– IEEE 1410 (Expulsion fuse guidance)

Operational Significance

The Abimat 20kV fuse cut-out remains indispensable in modern distribution systems. Its integrated fault interruption, positive disconnection visibility, and manual switching capabilities deliver unparalleled cost-to-reliability ratios. Proper fuse coordination—considering available fault currents and equipment withstand characteristics—prevents unnecessary upstream outages. When maintained per manufacturer guidelines and installed with appropriate animal guards and surge protection, these devices provide decades of service across utility, industrial, and renewable energy applications, forming the first line of defense against electrical faults in overhead networks.