Disconnect Switch Types: Essential Components for Power System Safety

Disconnect switches (disconnectors) provide critical visible isolation points in electrical power systems. They enable safe circuit de-energization for maintenance while enhancing operational safety. Unlike circuit breakers, disconnectors lack current-interrupting capability and operate only under no-load conditions or with minimal residual current. Various designs address specific voltage requirements, space constraints, and functional needs.

Primary Types by Construction

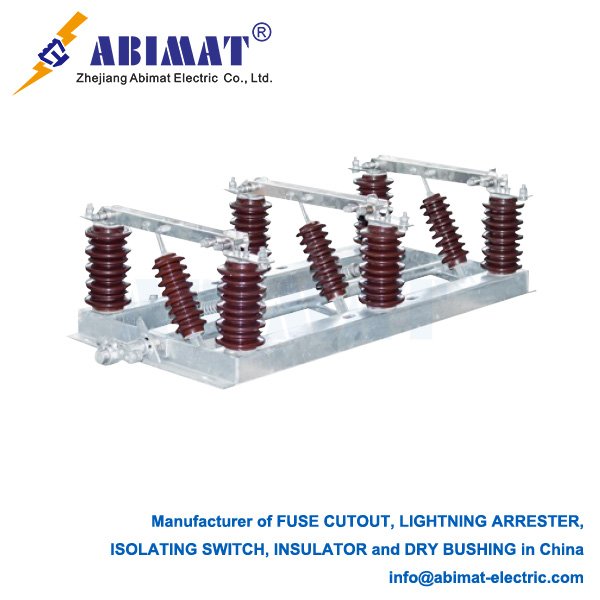

The center-break type has a design where two insulator columns hold up a central arm that rotates and moves horizontally. It works well in outdoor substations, handling high voltage (HV) and extra high voltage (EHV) up to 800kV. It’s built strong, has a clear visible gap, and has a track record of working reliably, but it does need a lot of horizontal space, which is a downside. The double-break type has three insulator columns with a central rotating arm that creates two breaks at the same time. It’s used in HV and EHV setups where space is tight, can handle higher voltages for its height, and saves space, though its mechanism is more complex than single-break designs. The vertical-break (pantograph) type has a scissor-like mechanism that moves up and down from a lower stack of insulators. You’ll find it in HV and EHV substations where space is limited, needing very little horizontal space with an easy-to-see gap, but it does require a lot of vertical space to work, which is something to note. The horizontal swing type has a single insulator column with an arm that rotates horizontally on it. It’s used in medium voltage (MV) and HV outdoor setups, being mechanically simple and not needing too much space, but it can only handle lower voltage and current levels, which is a downside. The enclosed type has contacts inside insulated enclosures that can use air, SF₆, or vacuum, and often they can also break loads. They’re used in indoor or outdoor MV switchgear (up to 38kV) and ring main units (RMUs), being compact, able to stand up to weather, and letting you switch loads. But there’s no visible gap, and you need status indicators to know how they’re doing, which is a limitation.

Functional Classification

Non-load-breaking disconnectors only provide isolation when there’s no load. They have an important safety feature: a visible gap in the air. Load-breaking switches do more. They not only isolate circuits but can also stop load currents. They use methods to control arcs, like spring mechanisms or interruption with SF₆ or vacuum. They’re really important for switching transformers and capacitors in medium voltage systems. Fused disconnectors have current-limiting fuses built into their structure. This means they can both isolate circuits and protect against overcurrents, which is useful for transformers and capacitors. Grounding (or earthing) switches keep people safe by connecting isolated circuits to the ground. There are different kinds: standard ones, make-proof ones that can handle faults, and those built into main disconnectors. Busbar disconnectors are special designs. They connect equipment to busbars. Some have transfer switches, which let you move connections between live busbars.

Selection Criteria

Several key factors affect how you choose a disconnector.

System voltage is one. It sets the rules for insulation.

Then there’s rated current. This covers how much current the disconnector can handle continuously and during short circuits.

Space matters too. The amount of room you have is key for planning a substation’s layout well.

What do you need the disconnector to do? Its job—like isolating circuits, breaking loads, grounding, or providing fused protection—matters a lot.

Where will it go? Environmental conditions, such as how polluted the area is, the risk of earthquakes, and whether it’s for indoor or outdoor use, play a part.

Safety can’t be ignored. You have to think about things like needing a visible gap between contacts and having proper grounding setups.

And don’t forget standards. The disconnector must meet rules like IEC 62271-102 and IEEE C37.32.

Conclusion

Abimat disconnectors are essential for keeping power systems running safely. Picking the right kind—whether it’s a center-break, vertical-break, enclosed, or some special type—depends on the voltage class, what it needs to do, and the limits of where it will be installed. If you understand how each type works, you can use them correctly. This makes the system safer when doing maintenance and helps the whole network work more reliably.