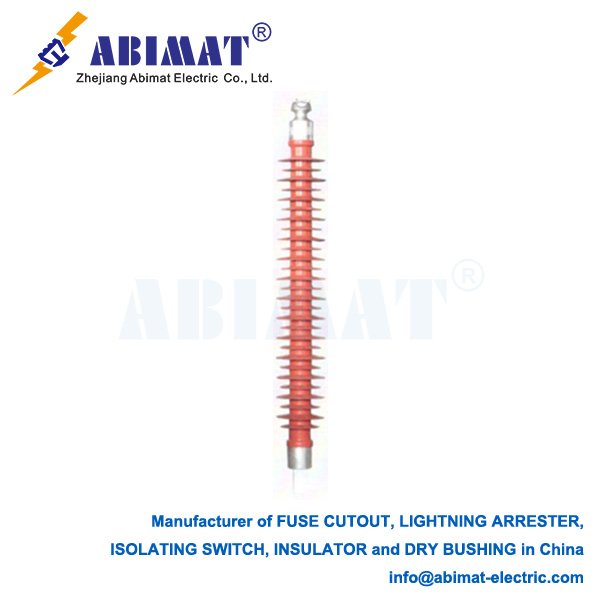

Composite Hollow Insulators: Engineered Performance for Modern Power Systems

Composite hollow insulators are a big step forward in electrical insulation tech. They’re now widely used instead of traditional porcelain in tough high-voltage jobs. Their special design gives them better performance and reliability.

Let’s start with their core structure and materials. At the center of each insulator is a cylindrical tube. This tube is usually made from Fiber Reinforced Polymer, or FRP for short. The FRP core is strong mechanically—it can handle high compressive and cantilever forces well. And it’s still light. Around the FRP tube is an outer housing. This housing is made of high-temperature vulcanizing silicone rubber, often called HTV silicone rubber. The housing has sheds with specific designs—some are alternating, some are aerodynamic. These sheds help make the creepage distance as long as possible. They also use silicone’s natural ability to repel water, which people call hydrophobicity.

These composite hollow insulators have lots of key advantages. For one, they work great even in polluted conditions. Silicone rubber repels water, so water forms beads and rolls off. This means way less leakage current, and it stops flashovers from happening in dirty or humid places. That’s a big plus compared to porcelain. They’re also really light—way lighter than porcelain insulators of the same size. Typically, they’re 70 to 90% lighter. This makes them easier to handle, transport, and install. It also cuts down on the cost of the structures that hold them up. They’re strong mechanically too. They can resist bending, twisting, and pressing forces well. That’s important for jobs like bushings or line traps. Unlike porcelain, they aren’t brittle and don’t explode. If they get hit or have internal faults, they won’t break into pieces in a dangerous way. This keeps people and equipment safer. They’re hard to vandalize too—they can take damage from gunshots or impacts without breaking easily. They handle UV light and bad weather well, too. The good-quality silicone used in them makes sure they work well for a long time, even in harsh environments. And since they’re hollow, the central hole lets things pass through—like conductors (used in bushings, for example), actuators, or sensing equipment.

You’ll find these insulators in many key places. They’re essential for Gas-Insulated Switchgear, or GIS, bushings. These bushings connect GIS to overhead lines or transformers. They’re also used in transformer bushings—these bushings bring conductors into transformers. They work as housings for surge arresters, giving insulation and mechanical support. They’re part of line traps, or wave traps, too—these are used in power line carrier communication systems. And they house sensors in instrument transformers, like current or voltage sensors.

The design of these insulators follows strict international standards. Examples include IEC 62217, IEC 60137, and IEEE C57.19.00/01. These standards cover what’s needed for electrical, mechanical, and environmental performance. Some critical things to get right are sealing the ends of the FRP core properly. The connections between the rubber housing, the core, and the metal end parts need to be strong and tight too. And during manufacturing, there has to be strict quality control to make sure everything is right.

To sum up, Abimat composite hollow insulators have a lot going for them. They work great electrically even in polluted areas, have a great mix of mechanical strength and light weight, are safer, and can be designed in different ways. Their reliability and the benefits they bring over their whole life mean they’re now the top choice for important high-voltage equipment. You’ll find them in modern power transmission and distribution networks all over the world.