Types of Fuse Cut-Outs: Essential Overcurrent Protection in Distribution Networks

A Fuse Cut-Out—also called Drop-Out Fuse or Fuse Disconnector—is a basic protective device. You’ll find it on overhead power lines, usually where power connects to transformers, capacitor banks, or feeders. It has three main jobs.

It stops too much current on its own. If there’s a short-circuit or a long-lasting overload, it shuts the current off to protect equipment downstream. It also makes a visible gap in the air. This lets you turn off equipment power so you can work on it safely. And it holds the fuse link—the part that gets used up—securely, so replacing it is easy.

There are different types of fuse cut-outs. They’re mostly different because of how they put out arcs and how they’re built.

The Open (Exposed) Link type is the simplest. It has a bare wire or small element between two contacts on an insulating base—you can see it clearly. It only uses air to put out arcs, but weather affects it. It’s rare now in modern setups; it can’t stop much current, might spark outside, and has safety issues. Sometimes it’s in old or very low-voltage systems.

Enclosed (Non-Expulsion) types have the fuse link inside a sealed or semi-sealed tube—made of fiberglass, composite, or ceramic. No gases escape. It uses the tube’s insulation and inside air (maybe sand too) to put out arcs. It’s clean, good for small spaces, but can’t stop as much current as expulsion types of the same size.

Solid-Material types are more advanced. The Abimat fuse is in grainy silica sand inside a strong sealed tube. When the fuse melts, the arc gets stuck in the sand. The sand melts a little to make a glass-like tube, which cools and stops the arc fast. It handles high currents (over 10kA), limits current well, and works quietly. But you need to replace the whole fuse assembly.

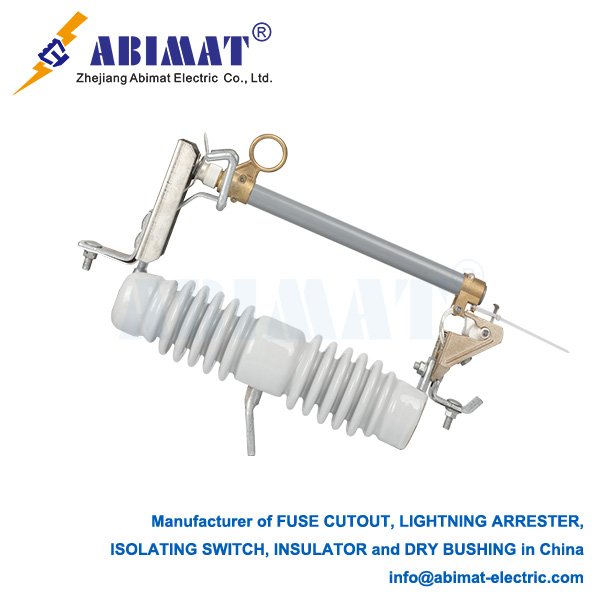

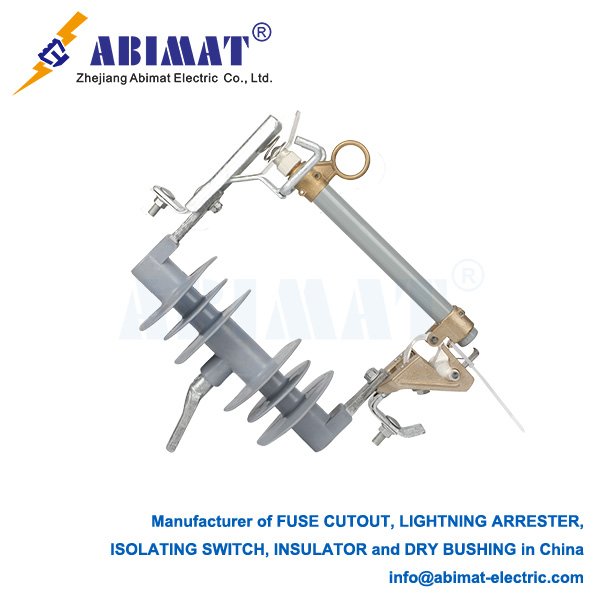

Expulsion types are most common for medium voltage (11kV, 33kV). The fuse link is in a hollow open tube—fiberglass or polymer—that lets out gases. When there’s a fault, the fuse melts, making an arc. Heat breaks the tube’s liner to make gas. The gas rushes out, stretching and cooling the arc to stop current. It’s cheap, easy to replace the fuse, but makes noise and needs space for gas. The fuse carrier drops down to show a fault.

Choosing one depends on system voltage (match or exceed line voltage), continuous current (carry normal load), interrupting rating (stop max fault current), and speed (like K/T—transformers need slow T links).

They follow standards like IEC 62271-111 and IEEE C37.41.

To sum up, types are based on arc extinction: Open Link (obsolete), Enclosed, Solid-Material, Expulsion. Expulsion is most common; Solid-Material works better when needed.