Overhead Fuse Cutouts

An overhead fuse cutout is an important protective device. It’s used a lot in electrical distribution systems—most often on overhead lines, for voltages up to 38kV. Its main jobs are two things: it stops fault currents, and it gives a clear visual way to isolate equipment. That equipment can be transformers, capacitors, or parts of feeder lines.

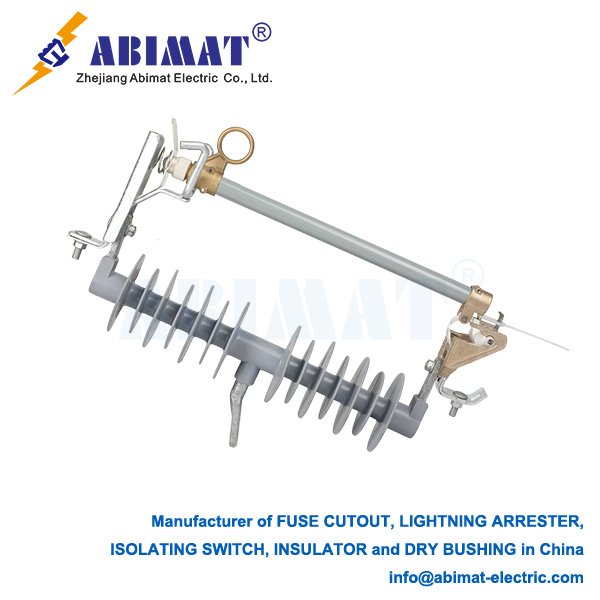

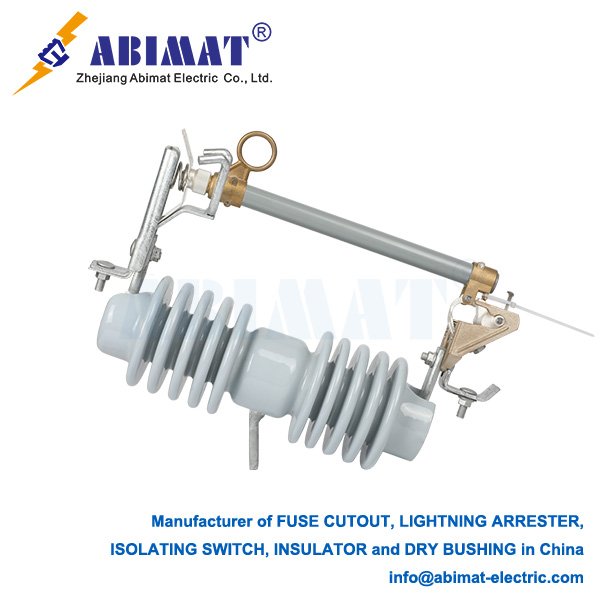

A standard fuse cutout has three main parts.

- The Body (or Housing): This is the outer part. It’s made of strong, weather-resistant material—either insulating polymer or porcelain. It does two key jobs: it holds up the parts that carry current, and it contains the arc when the fuse interrupts the circuit.

- The Fuse Holder: This part moves. People often call it the “fuse tube” or “door.” It holds the fuse link. It’s hinged at the bottom, and it’s made to swing and drop down when it works.

- The Fuse Link: This is a small part inside the fuse holder. It’s made to melt and split apart when there’s too much current, and it’s calibrated precisely to do that.

The cutout works on the “expulsion fuse” principle. When the circuit is running normally, current flows through the fuse link without stopping. But if there’s a steady overcurrent or a short-circuit fault, something changes. The fusible part inside the link melts. That melting creates an electric arc. The heat from this arc breaks down a fiberglass liner inside the fuse tube. This breakdown makes de-ionizing gases—lots of them, and fast. These gases push out quickly, and that action puts out the arc for good. It also stops the current from flowing.

When the link melts, it loses its mechanical tension. That tension loss makes the fuse holder release. After releasing, the holder swings down. It hangs straight down from its hinge. This is a clear, easy-to-see sign. That’s why people also call this device a “fuse drop-out”—the drop shows it’s worked, and the circuit is open. This visual cue matters a lot. It helps line crews find the faulty part of the circuit fast.

Abimat fuse cutouts have three main traits that define them: how much current they can interrupt, their voltage rating, and their speed (like fast or slow). They’re a good first line of defense for a few reasons: they don’t cost much, they’re reliable, and you can replace them right in the field. They isolate faults so expensive equipment—like transformers—doesn’t get damaged. They also keep the bigger distribution network stable. One thing you can’t skip: coordinating the fuse ratings correctly. This is key for “selective operation”—it makes sure only the faulty part of the circuit gets disconnected, not the whole thing.