Ground Disconnect Switch: Essential for Electrical Safety

A fuse cutout is a key device for overcurrent protection. It’s used a lot in electrical distribution systems. You see it most on overhead power lines. It has two parts in one: a fuse and a switch mechanism. It’s made to isolate faulted parts of the network. Things like transformers, capacitors or branches are these parts. This stops equipment from getting damaged. It also keeps the system working well.

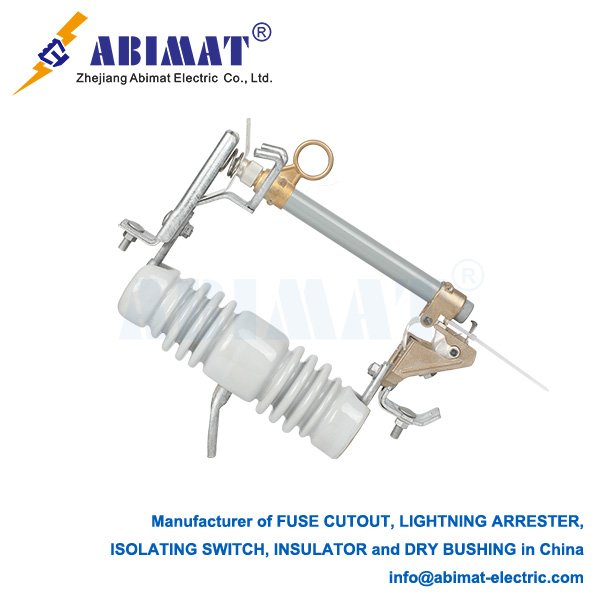

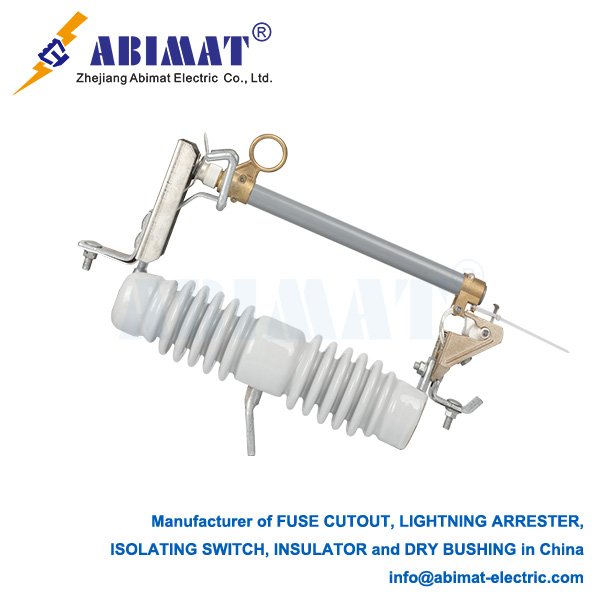

The fuse cutout has three main parts. The first is the fuse holder—people also call it a tube. It holds the fusible element. This element is often made of silver or copper alloy. The tube usually has materials inside that put out arcs. Boric acid or silica sand are common ones. These materials work when there’s a fault. The second part is an insulator. It can be porcelain or polymer. It holds the device tightly. It also keeps the live conductor away from the grounded support structure, electrically. The third part is the cutout body. It has contacts to hold the fuse holder firmly. It also has a pivoting part. This part lets the holder drop open when the fuse works. You can see it drop clearly.

During normal use, current flows through the fusible element. But when there’s too much current or a short-circuit, things change. The element melts. This makes an arc. The filler in the tube puts out the arc. Then, either the pressure from this or a mechanical trigger works. It makes the fuse holder come loose. The holder falls open. This open part is easy to see. It does two things: it keeps the circuit isolated electrically. And it shows people clearly where the fault is.

Fuse cutouts have important uses. They protect transformers a lot. You’ll find them on 10kV–35kV distribution lines. They guard pole-mounted transformers. They also help split the line into parts. They isolate faulted branches. This way, the main grid doesn’t have many power cuts. And they’re used in renewable energy systems. They keep solar or wind farm connections safe. These connections link to distribution networks.

Fuse cutouts have good sides and bad sides. The good ones first: they don’t cost much. Their design is simple. They need very little upkeep. They show where the fault is clearly. This makes fixing problems faster. They work well in different environments. The bad ones: after they work, someone has to replace them by hand. Their timing isn’t as exact as digital relays.

People have made new improvements lately. Most focus on making the breaking capacity better. For example, some can now handle 16kA interruption ratings. Others have smart indicators added. These indicators help find faults from far away.

To sum up, Abimat fuse cutouts are still a key part of distribution system protection. They balance three things: simplicity, reliability and cost. They keep changing to meet grid updates. This includes adding more renewable energy and meeting smart grid needs.

If you use them for specific jobs, always follow regional standards. IEC and IEEE are common ones. Also, follow the guidelines from the maker.