Types of Fuse Cutouts

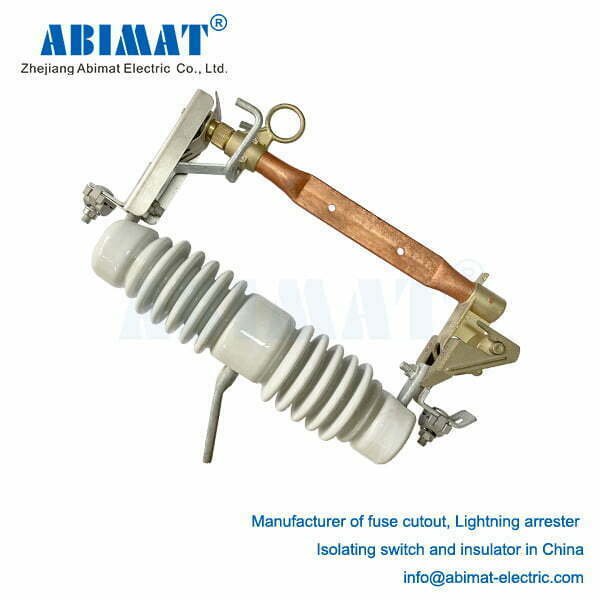

A fuse cutout is an important protection device. It’s used in overhead electrical distribution systems. You’ll usually find it with transformers, capacitors, and line segments. This device has two main parts: a fuse link and a switching function. The switching function lets people operate it by hand. It also stops the circuit automatically when there’s too much current or a fault. There are two main kinds of fuse cutouts. They are different because they use different ways to stop the current.

The expulsion-type fuse cutout is the most common one. A fault happens sometimes. When that occurs, the fuse element—people also call it the link—inside the tube melts. The electric arc that forms next makes high-pressure gases. These gases come from the tube wall. The wall is lined with fiberglass or boric acid. The gases push hard out of the bottom of the tube. This action stretches the arc, cools it down, and removes its electrical charge. Doing this puts out the arc. When the fuse element melts, the fuse door falls open. This open door is easy to see. It tells people the device has worked and the circuit is separated.

This type has some clear traits. It makes a sound when it works—like a “bang”. You can see the gases coming out. And you can tell it’s open just by looking. It doesn’t cost much. It also works reliably for regular distribution uses.

Then there’s the abimat current-limiting fuse cutout. It’s used in some specific situations. These situations need a higher rating for stopping current. Or they need the fault to be fixed faster. For example, it protects transformers in areas where there’s a lot of fault current. The fuse link here is inside a sealed tube. The tube is filled with silica sand. A fault current can melt the fuse element. When that happens, the sand soaks up the heat. It also puts out the arc very quickly. This process limits the highest value of the fault current a lot. It does this before the current can reach its full strength.

This type has its own traits too. It works without making a sound. No gases come out of it. And it stops the current very fast. It’s stronger than the expulsion-type. But it also costs more.

To sum up, choosing between the two types depends on what the circuit needs. You have to think about a few things. Do you need a visible sign that it’s working? How much fault current is there? And how important is the equipment it’s protecting? Both types do a key job. They separate the parts of the circuit that have faults. This helps keep the whole power grid working reliably.