The Drop-Out Fuse: A Vital Protective Device in Distribution Networks

A drop-out fuse—sometimes called an expulsion-type fuse—is a key device that protects against too much current. It’s used a lot in overhead medium-voltage distribution systems—usually 11 kV to 33 kV. It does two main jobs: it stops fault currents reliably, and it shows clearly when it’s worked. This helps isolate the broken parts of the network, like distribution transformers or feeder branches.

Parts of the Device

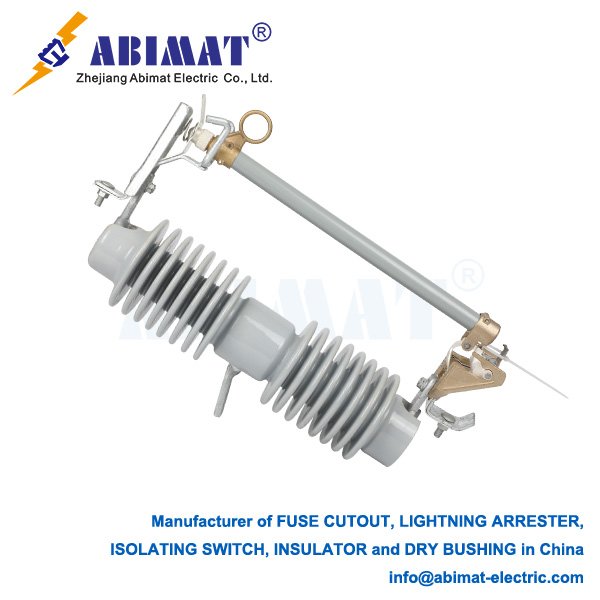

The device has three key parts.

The first part is the base. It’s a strong insulating structure fixed to the crossarm. It has upper and lower contact terminals.

The second part is the fuse holder—sometimes called a tube. It’s a hollow tube, usually made of fiberglass or phenolic resin. It’s made to hold the fuse link. The inside of the tube is designed to make and let out gases that stop arcs.

The third part is the fuse link. It’s a part you can replace. It’s set exactly to melt at a certain current and time. It carries the normal load current.

How It Works

When the load is normal, the fuse holder stays closed and up. The mechanical tension of the fuse link holds it that way. This creates a continuous path for current through the device.

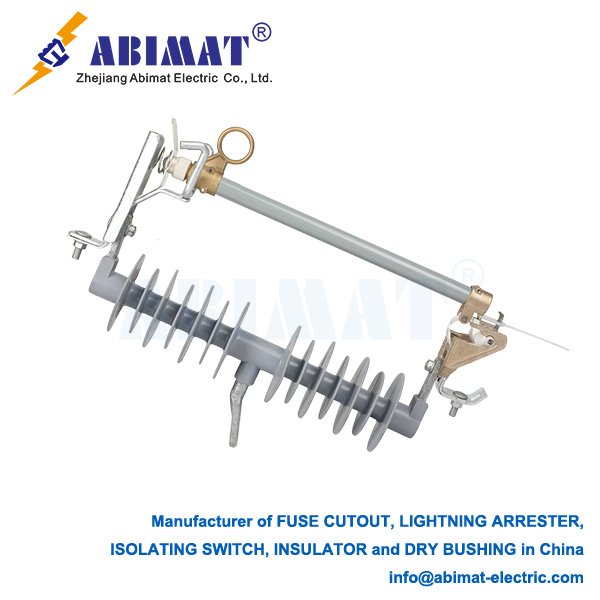

If there’s too much current for a long time, the fuse link gets hot and melts. This stops the circuit. The electric arc that forms inside the tube breaks down the lining material fast. This makes a lot of gas. The gas is pushed out lengthwise. This creates a blast. The blast stretches the arc, cools it down, and stops it from burning.

When the fuse link melts, it lets go of the tension that holds the tube. Then the holder can move freely on its lower hinge. Gravity pulls it down, so it swings downward. This “drop-out” action makes a clear, sure air gap. It tells people the fuse has worked, and it isolates the circuit downstream. This clear visual sign is a very important safety feature for line crews.

Good Points and Uses

People like drop-out fuses for these reasons:

They show when there’s a fault clearly—the dropped position lets everyone know if it’s worked.

They’re good for saving money. They work well and don’t cost much to protect against too much current.

They can isolate circuits too—the air gap acts as a physical barrier for safe maintenance.

They’re simple. Their strong mechanical design means they last a long time, and you don’t need to fix them much.

They’re mainly used to protect transformers mounted on poles, capacitors, and to divide overhead lines into sections.

Conclusion

The abimat drop-out fuse is still a key part of protecting overhead distribution systems. It combines two useful things well: it stops arcs reliably, and it gives clear visual signs. This makes it a device you can’t do without—it helps make the system more reliable and safer. To make it work well, you need to choose the right one, match it with the protection upstream, and check and fix it regularly.