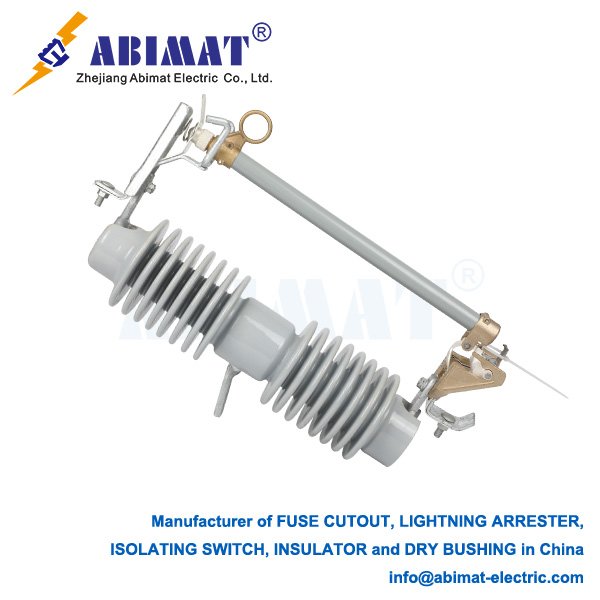

Ceramic Fuse Cutouts: Key Protection for Overhead Distribution

The polymeric drop-out fuse cut-out is a big change in the design of the classic overhead distribution protection device. It does the same main job as the old porcelain type—protecting transformers and feeders from overcurrents and giving a visible way to isolate them—but it uses modern materials and engineering. This gives it clear advantages in how it works.

The main way it operates stays the same: when there’s a fault, the fuse link melts. This stops the current, makes the fuse carrier let go, and swing down—and that creates a clear, easy-to-see break. The key difference is the material used for the housing. Instead of a brittle porcelain insulator, polymeric cut-outs are made from strong, lightweight engineering materials. Most often, these are fiberglass-reinforced polyester or similar compounds.

Key Advantages of Polymer Construction

One big advantage is better safety and how it fails. This is the most important benefit. Porcelain can break into pieces if someone shoots it, damages it on purpose, or hits it hard. That might make live parts fall down. But polymer housings aren’t brittle. If they get badly damaged, they usually stay together instead of shattering. That makes failures safer.

Another good thing is that polymer housings are much lighter than porcelain. This makes it easier to move, store, and install them. It also means less tired workers and lower risk of getting hurt. Plus, it puts less stress on the pole or structure that holds the fuse up.

Polymer housings also work better in dirty areas. Porcelain pulls water to its surface. Water can mix with dust and salt to make a layer that conducts electricity—and that can cause tracking, flashover, and power cuts. But many polymer materials push water away. This helps them work better near the coast or in industrial areas where there’s a lot of pollution. It makes them more reliable.

Polymer material is tough, too. It can handle more damage from accidental hits, animals, or vandalism like gunshots. This makes the fuses last longer and cuts down on maintenance costs.

Polymers also let us design the fuses more easily, and we can make them different colors. Different colors help workers tell which phase each fuse is for. They also look more modern and streamlined.

Considerations and Applications

People test polymeric drop-out fuses hard. They check if the fuses can handle UV rays, bad weather, and tracking—to make sure they work well for a long time. These fuses can replace porcelain ones directly. They’re perfect for harsh environments, areas where vandalism is common, and any place where better safety and easier handling matter most.

To sum up, the abimat polymeric drop-out fuse cut-out uses better materials to work like the old fuse cut-out. But it fixes the old one’s problems with safety, weight, and handling pollution. That makes it a strong, reliable choice for modern distribution networks.