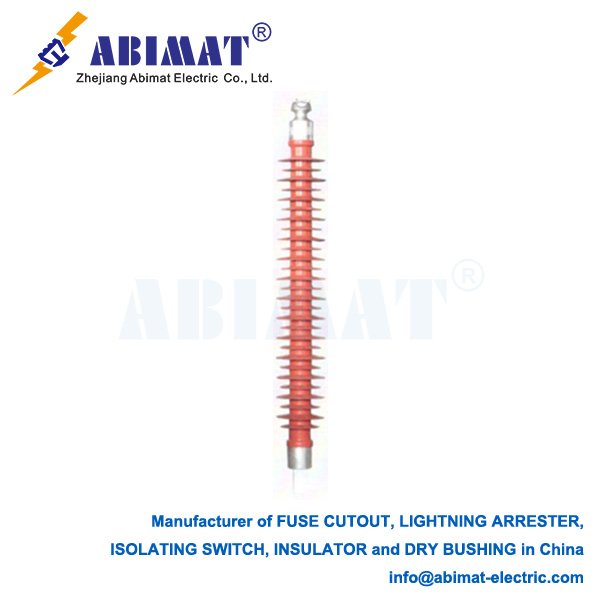

The 150kV Post Insulator: A Key Part in High-Voltage Systems

The 150kV post insulator is a basic but strong part used in electrical substations and high-voltage transmission systems. Its main job is to hold live conductors, buses, or switchgear parts in place (mechanically) while keeping them safely insulated from the ground. It’s designed for a system voltage of 150kV, and it’s built to work even when facing tough electrical, mechanical, and environmental stress.

Core Functions and Design Idea

When it works at these high voltages, the 150kV post insulator has to stand up to three things: the steady power-frequency voltage, sudden voltage spikes from switch use (transient overvoltages), and voltage surges from the air—like those from lightning. Its design has a long, smooth core (usually made of porcelain or glass) with a bunch of sheds or ribs around it. These sheds matter a lot: they make the “creepage distance” longer. Creepage distance is the path along the insulator’s surface—from the energized end to the grounded end. A longer path stops “flashover” (unwanted electrical discharge) by breaking up conductive paths. Those paths can form from pollution, moisture, salt, or dust.

Key Parts and Materials

Most 150kV post insulators have four main parts:

1. Insulating Core

This is the main body of the insulator. In the past, it was made of strong porcelain. Now, more and more use composite materials—like a fiberglass rod. This core gives the insulator its main ability to block electricity (dielectric strength).

2. Weathersheds

These are the outer parts around the core. For composite insulators, they’re made of high-quality plastic—such as silicone or EPDM rubber. For porcelain insulators, the sheds are glazed right onto the porcelain. Their job is to protect the core and make sure the creepage distance is long enough.

3. End Fittings

These are metal parts—usually galvanized steel or aluminum—on both ends of the insulator. They connect the insulator to the support structure (like a metal frame) and the live wire. The connection is often done with cement, swaging (squeezing), or compression. This makes sure the connection is strong mechanically.

4. Sealing System

Composite insulators need this part badly. It’s a seal at the interface—between the rubber sheds, the core, and the end fittings. Its job is to keep water from getting inside. This is super important for the insulator to last a long time.

Critical Performance Ratings

When you pick a 150kV post insulator, two main ratings matter most:

Mechanical Strength

These insulators are built to handle high “cantilever” or “compressive” strength. Usually, this strength ranges from 10 kN to 25 kN—sometimes even more. This lets them hold heavy busbars and stand up to wind and ice loads.

Electrical Traits

Key specs here include three things: first, the power-frequency voltage it can stand when dry or wet; second, the voltage from lightning hits it can take (for example, 650 kV or higher); third, a set creepage distance (like 3150 mm or more for areas with lots of pollution).

Summary

To sum up, the 150kV post insulator is a carefully made part. It’s vital for keeping high-voltage networks safe and working well. Its design makes sure it holds parts in place steadily and keeps insulation reliable—even when working in the hardest conditions.