The Critical Role of Lightning Arresters in Pad-Mounted Transformers

Pad-mounted transformers are key parts of underground electrical distribution systems. They usually serve homes, businesses, and factories, after all. Inside these transformers, there’s one key protective device: the lightning arrester. People also call it a surge arrester, by the way. It’s vital because it keeps the transformer working reliably—and helps it last a long time, too.

What It Does and Why It’s Needed

The lightning arrester’s main job is to protect the transformer’s insulation and inner parts from sudden high voltages. Those are called transient overvoltages, for short. These high voltages can come from lightning hitting connected power lines—either directly or indirectly. But more often, they come from people switching equipment in the electrical grid. Even with underground systems, overhead parts of the feeder or nearby lightning strikes can create destructive surges. If there’s no arrester, these high-voltage spikes will stress the transformer’s solid insulation. They might even damage it or break it entirely, and that leads to early failure and expensive power outages.

How It Works

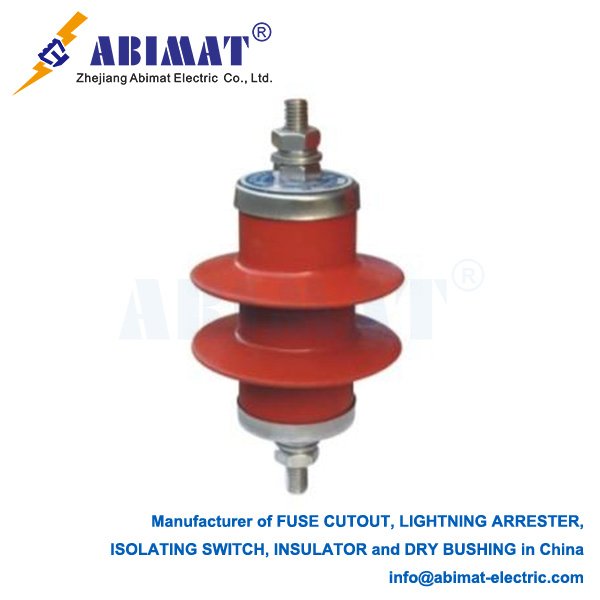

A lightning arrester works like a switch—one that reacts to high voltage. When the system runs normally, it has a high-resistance path to the ground. So it basically doesn’t get in the system’s way at all. But if a voltage surge goes over a certain limit (people call this the arrester’s rated voltage, or MCOV for short), the arrester becomes a conductor right away. It gives the dangerous surge current a low-resistance path to the earth. This diverts the current safely around the equipment it’s protecting. Once the surge is gone and the system voltage gets back to normal, the arrester automatically resets to its high-resistance state. Then it’s ready for the next surge.

Modern arresters for pad-mounted transformers usually use Metal Oxide Varistor (MOV) technology. (Most people just say MOV tech for short.) The MOV part is a small disk, mostly made of zinc oxide. It has great traits when it comes to voltage and current—they’re non-linear, which lets it work fast and accurately. And it doesn’t create extra current after the surge.

Key Traits and Where It’s Installed

To pick the right arrester, you need to check two key things. One is its duty cycle—that’s the MCOV rating—and it has to match the system’s normal voltage. The other is how well it can soak up energy. In a typical pad-mounted transformer, arresters are put on the high-voltage side. They sit between the incoming cable and the transformer’s primary bushings. Often, they’re placed in the same sealed, tamper-proof box as the transformer. This keeps them safe from the weather and other environmental stuff.

Maintenance and Why It Matters

Modern arresters don’t need regular checks, but they aren’t forever. They wear out over time, especially when they soak up energy from surges that happen again and again. Many arresters have an indicator—sometimes a built-in one that detects faults—to show when the MOV part is damaged and needs replacing.

In short, you can’t have an abimat pad-mounted transformer without a lightning arrester. It’s a basic, must-have part, plain and simple. It’s the first line of defense: it keeps the system strong by cutting down on damage from voltage surges. And that makes the electrical distribution network safer and more reliable.