Fuse Cut-Out Polymers: A Self-Protecting Tool in Electronics

In electronic circuit protection, fuse cut-out polymers are a smart and self-reliant safety technology. They aren’t the traditional fuses you might think of. Instead, they’re a special kind of polymer mix—often called Positive Temperature Coefficient (PTC) materials or resettable fuses. Their main job is to keep electronic circuits safe from harm caused by too much current, like when a short circuit happens or a device uses more current than it should.

Fuse cut-out polymers work based on a simple rule. Their electrical resistance changes dramatically—and reversibly—with temperature. Normally, the polymer is filled with conductive particles, like carbon black. These particles form a connected web, letting electricity flow through with little resistance.

But when an overcurrent happens, the material heats up. That heat comes from the electricity passing through it, a common effect called Joule heating. Once the temperature hits a certain point—we call this the “switch” or “trip” temperature—the polymer itself expands a lot. This expansion breaks the connected web of conductive particles. Suddenly, the material’s resistance jumps by many times. It goes from something that lets electricity through to something that blocks it.

This “tripping” slows the current way down. That’s how it protects the sensitive parts of the circuit that come after it.

One big plus of these polymers, compared to regular one-time fuses, is that they can reset themselves. You fix the problem first, then turn the power off and on again. The polymer cools down and shrinks back to its original size. The conductive particles reconnect, and the device goes back to having low resistance—ready to work normally once more. This self-healing feature means you don’t have to replace them by hand. It makes them perfect for devices where reliability and easy maintenance matter most.

These materials have some key traits you need to know. There’s the “hold current”—that’s the maximum steady current they can handle. Then there’s the “trip time,” the maximum voltage they can take, and their resistance in both working and tripped states.

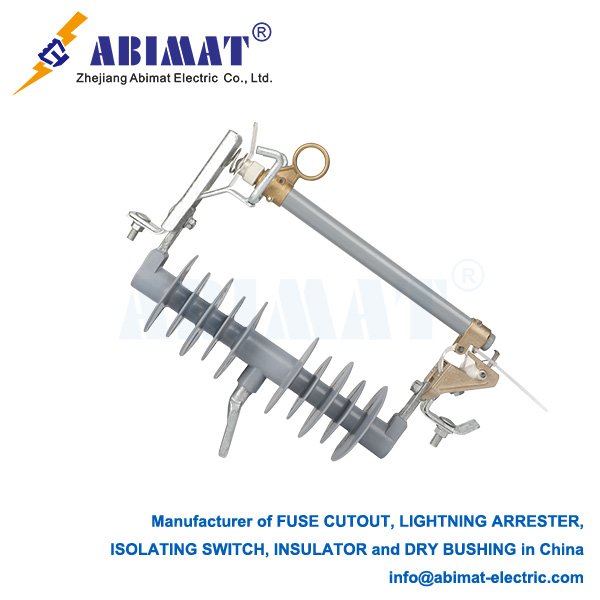

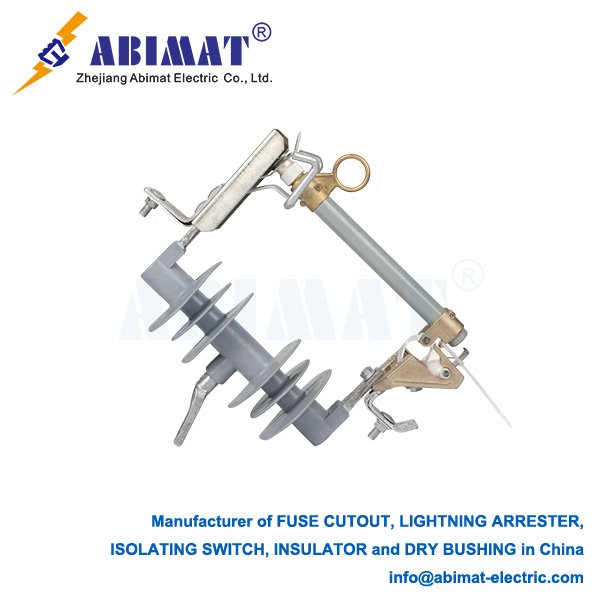

Abimat fuse cut-out polymers are everywhere. You’ll find them in everyday electronics: they protect the USB ports and battery packs in laptops and phones. They’re also vital in car electronics, industrial control systems, and telecom equipment. They offer strong, maintenance-free protection against overcurrent in complex setups. By being reliable and resettable, they play a key role in keeping modern electronic devices safe and long-lasting.