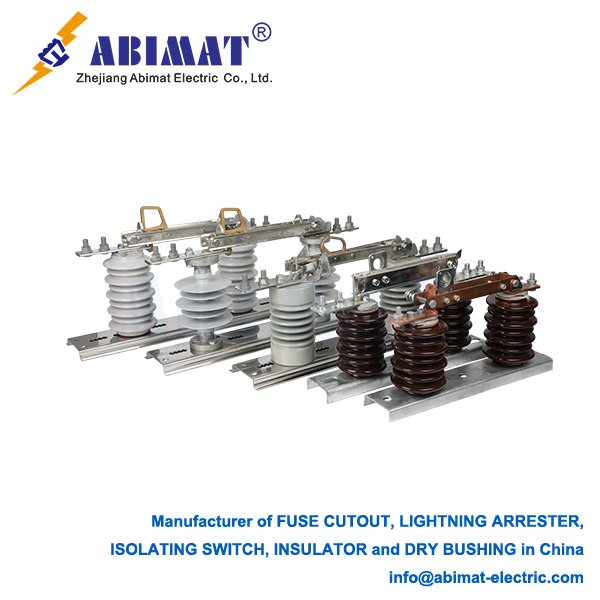

11 kV Disconnecting Switch: Critical Safety Component in Medium-Voltage Systems

The abimat 11 kV disconnecting switch (disconnector) provides fundamental safety isolation in medium-voltage distribution networks. Functionally distinct from circuit breakers, it establishes a visible isolation gap compliant with IEC 62271-102 to enable safe equipment maintenance, system reconfiguration, and personnel protection.

Functional Requirements & Design Standards

Core Functions:

– Establish visible air gap isolation (minimum 150 mm phase clearance)

– Facilitate safe isolation of transformers, cables, and switchgear

– Enable feeder sectionalizing without network de-energization

– Provide integrated earthing interface per IEC 61936-1

Technical Parameters:

– Rated Voltage: 12 kV (IEC) / 15 kV (ANSI)

– Continuous Current: 630A to 1250A

– Short-time Withstand: 20 kA rms for 3 seconds

– Impulse Withstand: 95 kV BIL (Basic Impulse Level)

– Operating Duty: Manual rotary mechanism or motorized actuator

Critical Design Elements

Contact Configuration:

– Single-break type: Horizontal rotary blade (compact AIS applications)

– Double-break type: Vertical-break assembly (enhanced dielectric performance)

– Self-aligning contacts: Copper-tungsten arcing tips maintaining contact resistance ≤50μΩ

Insulation Coordination:

– Phase-to-phase clearance: ≥150 mm

– Composite insulators: Silicone rubber housing (Pollution Degree IV per IEC 60815)

– Minimum creepage distance: 31 mm/kV

Safety Integration:

– Mechanical interlocks preventing load-break operation

– Dual-padlocking provisions (ISO 14119 compliant)

– Mechanically coupled position indicators

Mandatory Operational Protocols

Prohibited load interruption: Limited switching capability to:

– Transformer magnetizing currents ≤5A

– Capacitive charging currents ≤3A (IEC 62271-102 Annex C)

Sequential isolation procedure:

– De-energize circuit via upstream protective device

– Verify de-energization

– Operate disconnector

– Engage earthing blades

Application Profiles

Distribution Networks:

– Transformer primary/secondary isolation

– Ring Main Unit feeder selection

– Shunt capacitor bank disconnection

Industrial Power Systems:

– 11 kV motor feeder isolation

– Generator circuit isolation

– Bus section segregation

Overhead Line Applications:

– Pole-mounted disconnectors (IP55 environmental rating)

– Air-Insulated Switchgear disconnection points

Maintenance & Verification

Performance Validation:

– Contact erosion inspection (max. 20% material loss)

– Operating torque measurement (≤150 Nm)

– Insulation resistance testing (≥100 MΩ at 5 kV DC)

– Blade alignment verification (±1.5° tolerance)

Type Test Requirements (IEC 62271-1):

– Power frequency withstand: 28 kV RMS for 1 minute

– Lightning impulse withstand: 95 kV peak

– Mechanical endurance: 1,000 operating cycles

– Temperature rise test: 65°C max. at rated current

Technology Evolution

– Motorized operation: SCADA-integrated actuators

– Condition monitoring: Embedded temperature/position sensors

– Hybrid switchgear: Vacuum interrupter integration for load-break capability

– GIS variants: SF₆-insulated compact designs