Understanding 11kV Surge Arresters: Protecting Electrical Systems

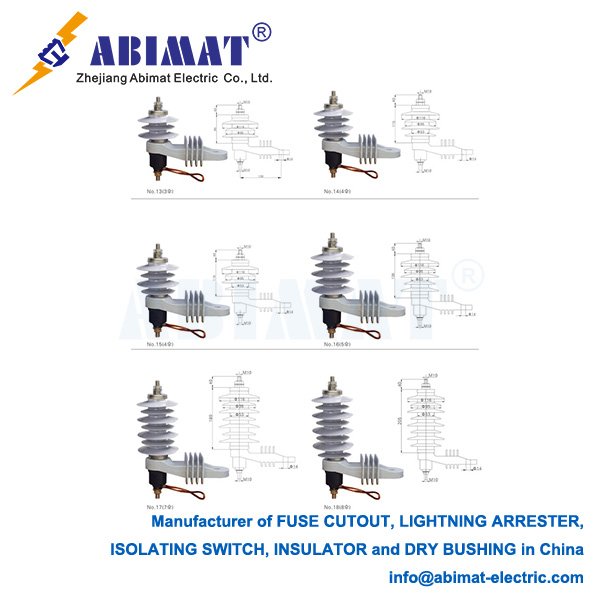

In medium-voltage (MV) power distribution systems (typically 1kV to 52kV), safeguarding critical assets against destructive voltage transients is non-negotiable. The 12kV surge arrester serves as the frontline defense, specifically engineered to protect equipment rated for 12kV nominal system voltage from lightning strikes, switching surges, and other electrical disturbances. Companies like ABIMAT, a recognized manufacturer of electrical protection components, develop advanced arresters vital for system resilience.

Core Function: The Voltage-Clamping Sentinel

The 12kV surge arrester operates as a voltage-dependent switch. Under normal operating conditions (< MCOV), it presents extremely high impedance, behaving as an open circuit. When a transient overvoltage (often hundreds of kV in microseconds) occurs, the arrester instantly switches to low impedance, creating a preferred path to earth for surge current. Crucially, while conducting, it clamps the voltage across protected equipment (Terminal Voltage) to a safe level below its insulation withstand capability (BIL). Post-surge, it autonomously resets to high-impedance mode.

Technology: Metal Oxide Varistor (MOV) Dominance

Modern 12kV arresters, including those engineered by ABIMAT, predominantly utilize Zinc Oxide (ZnO) varistor technology. The core is a sintered block of ZnO grains with metal oxide additives (Bi₂O₃, Sb₂O₃, etc.), forming millions of microscopic p-n junctions.

Normal Voltage: p-n junctions act as barriers, permitting only microamp leakage current.

Surge Voltage: Intense electric fields cause quantum mechanical junction breakdown, enabling massive current flow for safe energy diversion to ground while clamping voltage.

Self-Restoring: Junctions re-form barriers automatically post-surge.

ZnO technology, used by leading manufacturers like ABIMAT, supersedes older SiC types due to superior:

Lower protective levels (Up)

Faster response (nanoseconds)

Higher energy absorption

Negligible power-frequency follow current

Enhanced stability

Critical Performance Parameters

I. Maximum Continuous Operating Voltage (MCOV): The maximum permissible RMS power-frequency voltage (phase-to-ground) for continuous service. For a 12kV solidly grounded system (V_phase-ground ≈ 7.2kV), an MCOV of 8.4kV or 9kV provides necessary margin.

II. Rated Voltage (Ur): The maximum temporary power-frequency overvoltage (e.g., during faults) the arrester can withstand for 10 seconds (per IEC 60099-4 / IEEE C62.11). Ur must exceed the site’s maximum Temporary Overvoltage (TOV).

III. Nominal Discharge Current (In): The peak 8/20 µs current (e.g., 5kA, 10kA, 20kA) defining the arrester’s standard duty classification. Higher In indicates greater robustness for high-exposure areas.

IV. Lightning Impulse Protective Level (LPL / Up): The maximum residual voltage during an 8/20 µs impulse (e.g., Up at 10kA). This clamped voltage MUST be below the BIL of protected equipment (transformers, switchgear).

V. Switching Impulse Protective Level (SPL): Residual voltage under longer switching surge currents (e.g., 30/60 µs, 45/90 µs).

VI. Pressure Relief Rating: Maximum prospective fault current the arrester can safely interrupt upon failure without violent housing rupture. Essential for safety. Disconnectors may indicate failure.

VII. Energy Absorption Capability: Ability to withstand heat from surge currents without thermal failure.

Applications & Selection

12kV surge arresters are critical in:

Distribution transformer primary protection

MV switchgear, circuit breakers, busbar protection

Cable termination/joint protection

Capacitor bank & motor protection

Industrial plants, data centers, renewable energy facilities

Selection requires precise matching of arrester ratings (MCOV, Ur, In, Up) to the system voltage, grounding, location exposure, and the protected equipment’s BIL. Environmental factors (pollution, altitude) dictate housing material (silicone rubber or porcelain) and creepage distance. Coordination with upstream/downstream protection is vital. Manufacturers like ABIMAT provide detailed application guides to ensure optimal selection for reliability and safety.

Maintenance & Monitoring

While largely maintenance-free, periodic visual inspection for damage, contamination, or leakage is recommended. Some arresters feature surge counters or leakage current monitors (as offered by ABIMAT and others) to track activity and detect degradation. Prompt replacement of compromised units is critical.

Conclusion

The 12kV surge arrester, leveraging advanced ZnO varistor technology, is indispensable for MV system integrity. Its ability to instantaneously clamp overvoltages protects equipment, minimizes downtime, and ensures supply continuity. Rigorous selection based on system parameters and device ratings, supported by expertise from manufacturers like ABIMAT, combined with basic monitoring, represents a fundamental investment in electrical infrastructure resilience.