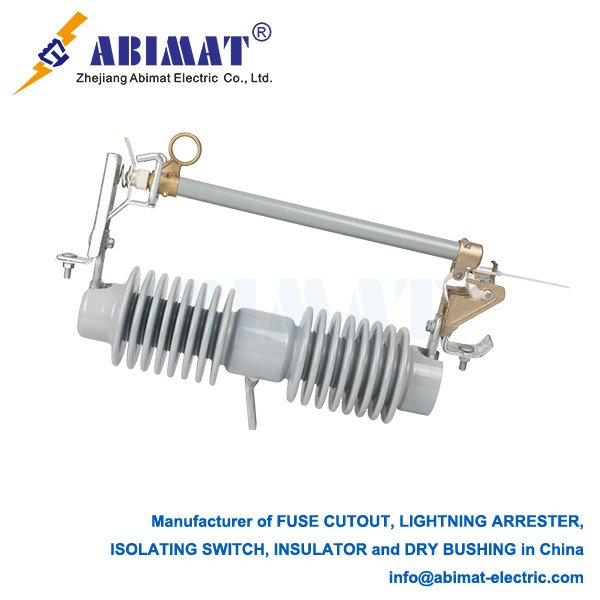

Fuse Cutout Switches: Essential Protection Devices in Medium-Voltage Distribution Systems

Fuse cutout switches serve as critical protection and isolation components in overhead distribution networks, typically operating at 15 kV to 38 kV. These devices integrate three fundamental functions: overcurrent protection through fuse operation, visible circuit isolation, and manual switching capability for maintenance operations.

Design and Operational Principles:

Fuse Protection Mechanism: Contains a precisely calibrated fuse element (commonly tin-silver alloy) designed to melt under sustained fault currents. This action disconnects faulted sections from the network.

Visible Disconnection: Upon fuse operation, the pivoting fuse holder assembly drops to a downward position, providing unambiguous visual confirmation of the interrupted circuit.

Isolation Function: Linemen manually operate the switch using insulated hot sticks to establish a visible air gap for maintenance safety, complying with lockout/tagout (LOTO) requirements.

Key Technical Features:

I. Expulsion Fuse Tube: Fabricated from fiberglass-reinforced polymer (FRP), this component channels arc-generated gases downward to extinguish the arc within 0.5–2 cycles of fault initiation.

II. Sealed Insulation System: Features hydrophobic cycloaliphatic epoxy or polymer housings with minimum creepage distances of 25 mm/kV. Silicone rubber seals prevent moisture penetration.

III. Dielectric Performance: Designed with Basic Impulse Level (BIL) ratings from 95 kV to 150 kV to withstand lightning surges and switching transients.

IV. Current-Limiting Action: Fast-acting fuse links (T-speed characteristic: 0.01–10 seconds) restrict prospective fault currents below 10 kA, protecting downstream equipment.

Performance Specifications:

– Rated Voltage: 15–38 kV (IEC 62271-111, IEEE C37.41)

– Maximum Interrupting Current: 8–16 kA RMS symmetrical

– Mechanical Endurance: Minimum 200 full-load operations (IEC 60282-1)

– Withstand Voltage: 50 kV power frequency for 1 minute (dry conditions)

Primary Applications:

Protection for pole-mounted distribution transformers

Sectionalizing points on overhead feeders

Switching for capacitor banks

Interconnection points for distributed renewable resources

Operational Advantages:

I. Rated Fault Clearing: Interrupts faults within two cycles, minimizing thermal damage to system components.

II. Positive Disconnection: Gravity-assisted drop-out mechanism ensures physical isolation independent of operator action.

III. Contained Arcing: The expulsion design prevents external arcing, maintaining incident energy below 2 cal/cm² at 38 kV.

IV. Maintenance Safety: Visible open gap enables compliance with OSHA LOTO procedures.

Standards Compliance and Maintenance:

Dielectric Testing: Includes separate wet and dry power frequency tests per IEC 62271-1

Coordination Requirements: Fuse time-current characteristics must coordinate with upstream/downstream devices per IEEE 242 guidelines

Field Maintenance: Requires annual infrared inspections (investigate >10°C temperature differentials) and pollution monitoring (cleaning threshold: 0.1 mg/cm² ESDD)

Technical Evolution:

Smart Devices: Incorporate current sensors with LoRaWAN or NB-IoT transmitters for fault location identification

Advanced Materials: Silicone rubber composite insulators replacing porcelain for seismic resistance and vandalism protection

Environmental Adaptation: UV-stabilized polymer formulations for extended service in ambient temperatures to 60°C

Conclusion

Abimat fuse cutout switches remain fundamental components for distribution system protection due to their electromechanical reliability. Proper selection of speed classes (K/T/S) and adherence to IEC/IEEE standards ensure effective coordination and personnel safety. Integration of monitoring capabilities continues to enhance their role in modern grid architectures while maintaining the fail-safe operation essential for field safety.