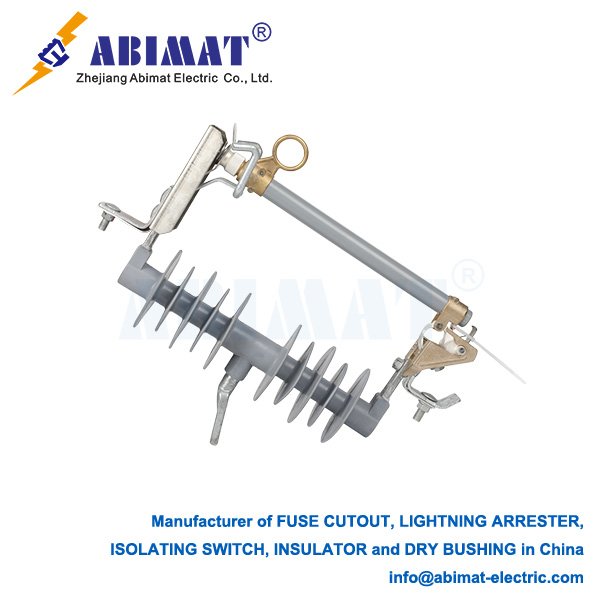

Dropout Fuse Cutout Covers: Critical Protection for Distribution Systems

Dropout fuse cutouts (DFCs) serve as vital overcurrent protection devices in medium-voltage distribution networks (typically 15–38kV). Their polymer covers—often overlooked—play essential roles in safety enhancement, equipment longevity, and system reliability. This article examines the technical functions, design evolution, and operational imperatives of these components.

Core Functions of Cutout Covers

- Arc Containment

During fuse operation, polymer covers withstand internal arcs >10kA/0.1s. Materials like glass-reinforced polyester (GRP) or thermoplastic elastomers (TPE) provide:

– Arc resistance up to 180°C continuous

– Tracking resistance >600 V per IEC 60587

– Containment of molten metal ejecta

- Environmental Sealing

IP67-rated covers prevent:

– Moisture ingress (critical for coastal/high-humidity zones)

– Salt/chemical contamination reducing creepage distance

– Ice accumulation disrupting dropout mechanism

- Wildlife Protection

Covers with smooth profiles and insulating skirts reduce animal-caused outages by 92% (EPRI study). Features include:

– 360° ribbed barriers against squirrels/snakes

– UV-stabilized coatings (>20-year service life)

Material & Design Evolution

Generational Shifts:

| Era | Material | Key Advancement | Limitation |

|---|---|---|---|

| 1980s-90s | Porcelain | High compressive strength | Brittle fracture risk |

| 2000s | EPDM Rubber | Elastic recovery >85% | Ozone degradation |

| 2010s+ | Silicone Composite | Hydrophobicity recovery <5min | Higher cost |

Modern designs incorporate:

– Pressure-relief vents: Direct arc gases upward at 30° angle

– Dual-durometer seals: Hard inner frame + soft outer gasket

– RFID tags: Enabling asset tracking via handheld scanners

Failure Modes & Maintenance Protocols

Critical Risks from Damaged Covers:

– Flashover Events: Cracks >3mm allow moisture paths, reducing BIL by 40%

– Fuse Non-Dropout: Corroded hinges increase operating torque beyond 50 N·m

– Phase-to-Phase Faults: Missing covers invite bird bridging (85% of avian outages)

Inspection Standards (per ANSI C37.41):

- Infrared thermography: ΔT >15°C indicates internal degradation

- Hydrophobicity testing: HC1–HC7 classification per IEC 62073

III. Mechanical force test: Verify hinge torque <35 N·m annually

Smart Cover Innovations

Leading manufacturers now integrate:

– Wireless CT sensors: Monitor leakage current >10mA

– Self-tightening mechanisms: Shape-memory alloys compensate for seal compression

– Photocatalytic coatings: TiO₂ nanoparticles decompose organic pollutants

Standards Compliance

Complies with:

– IEC 60099-4 (Metal-oxide surge arresters)

– IEEE C62.11 (Standard for MOV arresters)

– ANSI/IEEE C62.22 (Application guide)

Failure Mechanisms

Moisture Ingress: Degrades MOV blocks (detected via rising leakage current)

Thermal Runaway: Caused by continuous overvoltage or contamination

Energy Overstress: Exceeding rated kJ capacity

Seismic Damage: Cracked porcelain/polymer housings

Conclusion

The ABIMAT Dropout fuse cutout covers transcend simple environmental shields—they are engineered safety systems preventing cascading failures. With utilities facing increased wildfire risks and storm hardening mandates, next-generation covers combining real-time monitoring, self-healing materials, and enhanced arc containment will become grid resiliency cornerstones. Proper maintenance remains critical: a $200 cover replacement prevents average $18,000 outage costs (IEEE 1366 data).