Air Disconnect Switches: Critical Components for System Safety & Flexibility

While often grouped with circuit breakers, Air Disconnect Switches (ADS) serve distinct, vital roles in electrical power infrastructure. Their core purpose is to establish a safe, visible, and reliable physical air gap in de-energized circuits. This isolation is fundamental for personnel safety during maintenance (“Lockout/Tagout”), equipment servicing, and system reconfiguration. Unlike breakers, ADS lack any significant current interruption capability and operate solely on the principle of physical contact separation using ambient air as insulation.

Core Functionality & Operational Context:

I. Isolation Assurance: The primary function is unambiguous isolation. When opened, the physical air gap provides visual confirmation that a circuit section is disconnected from its voltage source, a non-negotiable safety requirement per standards like IEEE C37.20.2 and IEC 62271-102.

II. No-Load Operation: ADS are strictly make-or-break devices for unloaded circuits only. Opening under load current creates a destructive, sustained arc. Operation must always follow de-energization by an upstream interrupting device (e.g., circuit breaker). Interlocks often enforce this sequence.

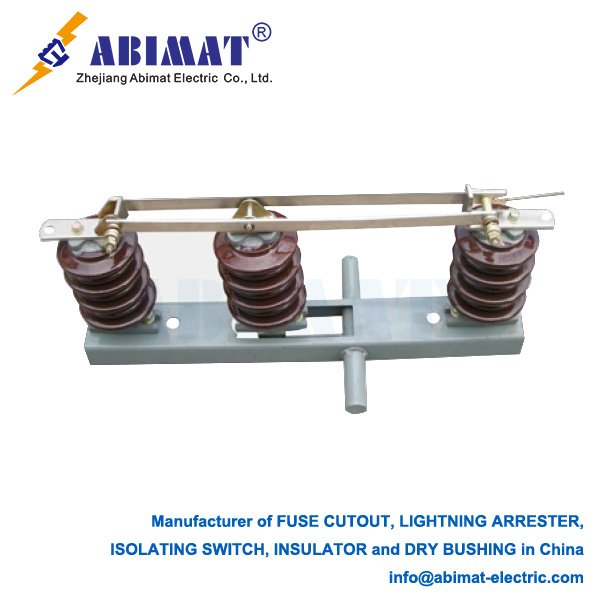

III. Voltage Withstand & Dielectric Integrity: In the open position, the switch must reliably withstand system operating voltage and specified transient overvoltages (BIL – Basic Impulse Level). The design of the air gap, arcing horns (to control and extinguish small incidental arcs), and insulating supports (porcelain or polymer) are critical.

IV. Earthing Integration: ADS are frequently paired with integrated or separate Earthing Switches (Grounding Switches). Once isolated, the earthing switch provides a safe, visible ground connection to discharge capacitive energy and ensure the isolated section remains at earth potential during work.

Key Design Variations & Selection Criteria:

Voltage Class: Ranging from Medium Voltage (MV, e.g., 5kV-38kV) to Extra High Voltage (EHV, e.g., 145kV-765kV), design complexity increases significantly with voltage. EHV switches often feature multiple breaks per phase.

Mounting Style:

Dead Tank: The switch enclosure (tank) is at earth potential. Common for higher voltages and GIS (Gas-Insulated Switchgear) bushings.

Live Tank: The interrupting chamber is at line potential, supported by an insulated column. Common for outdoor substations.

Contact Movement:

Vertical Break: Contacts separate vertically. Offers good pollution performance (self-cleaning by rain) and compact horizontal footprint.

Center Break: Contacts rotate horizontally from a central pivot. Often used for lower ratings or indoor applications.

Pantograph (Semaphore): Uses a folding linkage, providing a high vertical break in a relatively compact design.

Operation: Manual (via rotating handle and gearbox with visible position indicator), motor-operated (remote control), or occasionally pneumatic/hydraulic. Motor drives are essential for remote operation and interlocking schemes.

Enclosure: Outdoor switches are exposed to environmental stresses (wind, ice, pollution). Indoor switches are often housed within metal-clad switchgear, providing “dead-front” safety (no exposed live parts when closed).

Critical Applications Beyond Basic Isolation:

- Bus Sectionalizing: Dividing busbars into isolated sections enhances system flexibility, allows partial maintenance without full shutdown, and limits fault impact.

- Bypass Operation: Facilitating the isolation and bypass of critical equipment like circuit breakers or transformers for maintenance using transfer bus schemes.

III. Capacitor Bank Switching (De-Energized): Isolating capacitor banks after they have been de-energized by a breaker. (Note: Dedicated Load Break Switches or breakers handle energization/de-energization due to capacitive currents).

- Generator Isolation: Providing the main point of isolation between a generator and the step-up transformer or grid connection for safe maintenance.

- Temporary Feed Routing: Enabling safe reconfiguration of distribution feeders for repair or load transfer.

Essential Safety & Operational Considerations:

Strict Adherence to Procedures: Operating ADS under load is extremely hazardous. Rigorous switching procedures and interlocking are mandatory.

Visible Verification: The open air gap is the primary safety indicator. Auxiliary contacts for remote signaling supplement but never replace visual verification for safety grounding.

Mechanical Endurance: Designed for infrequent operation (typically hundreds to thousands of cycles), but must remain reliable over decades, often in harsh environments. Regular inspection and lubrication are key.

Corona & Radio Interference Voltage (RIV): Critical design factors at HV/EHV to prevent excessive discharge and electromagnetic interference.

Conclusion

Abimat Air Disconnect Switches are indispensable safety devices, not current interrupters. Their value lies in providing a definitive physical break and visible isolation point. Proper selection (voltage, mounting, operation type), integration with earthing switches, strict adherence to operational limits (no-load switching only), and rigorous safety procedures are paramount. They underpin system flexibility for maintenance and reconfiguration, forming a foundational layer of safety and operational control in power networks worldwide.