Composite Tension Insulators: Technical Overview

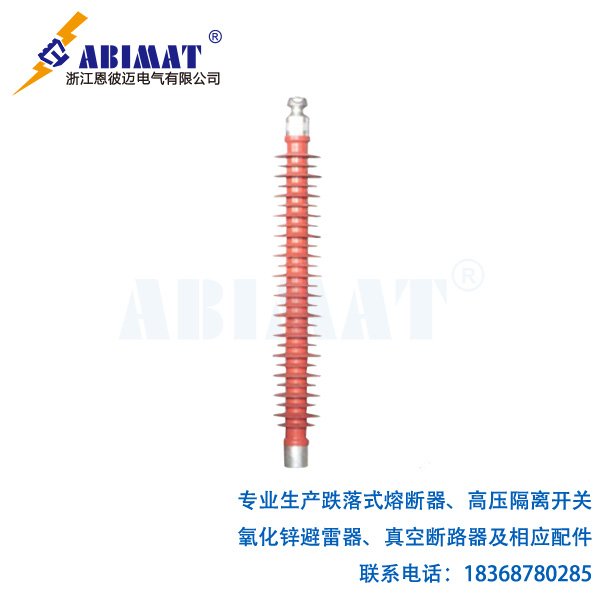

Composite tension insulators—often called composite strain insulators—are key in overhead transmission lines. Engineers fit them to strain towers, such as dead-end or angle structures, because they must handle high pulling forces.

They replace older porcelain or glass insulators. Made by combining a fiber-reinforced polymer (FRP) core, a silicone rubber cover, and metal end pieces, this design gives them strong mechanical strength and good electrical performance. It works especially well in tough environments.

Structure and Materials

The core rod uses epoxy-impregnated glass fiber-reinforced plastic (GFRP). Manufacturers pick this material for its high tensile strength—at least 1,000 MPa—and low density, around 2 g/cm³. It bears the main mechanical load.

Weathersheds are made from high-temperature vulcanized silicone rubber (HTV SR). This material naturally repels water, a key feature stopping pollution-caused flashovers. It keeps water from forming a continuous conductive film on the surface, working better in dirty, coastal, icy, or foggy spots.

End fittings are hot-dip galvanized steel. They connect the insulator to the tower and conductor. The insulator’s performance depends much on the tight seal between the core rod and these fittings. Extreme temperatures can make the two materials expand differently here, weakening their bond.

Performance Advantages

Composite insulators are strong for their weight—5 to 10 times more than steel. This puts much less strain on the towers holding them. They pass tough fatigue tests, too: bending 200,000 times at 27 Hz, or handling wind shakes, shows they last long without wearing out.

Electrically, they work better than many. The silicone rubber cover shares its water-repelling trait with dirt on the surface. This often doubles their pollution flashover voltage compared to similar porcelain insulators. In really dirty areas, you almost never need to clean them.

They stand up to different environments, working reliably from −40°C to +40°C. But their pulling strength can drop at these extremes. The issue? End fittings and core rod expand differently with heat or cold. Staying in high temperatures a long time alone can cut their bond strength by over half.

Design Considerations for Tension Applications

Ultra-high voltage direct current (UHVDC) projects—think ±800 kV systems—often need composite tension insulators rated over 300 kN for V-string setups. Engineers use finite element analysis to check dynamic stresses: ice falling off, conductors galloping, or wind sway. These events can make static loads 1.5 to 2.5 times stronger, so designs need good safety factors.

Installers must ensure end fittings rotate freely. This cuts bending or twisting stress during setup and use. Using two insulators side by side (parallel strings) boosts reliability; it also spreads torque better in tough strain uses.

Good designs include thermal disconnectors, which isolate worn core parts. International standards—IEC 61109, GB/T 19519—set strict tests, making sure the design lasts over 30 years.

Standards and Applications

Composite tension insulators mainly follow IEC 61109 and GB/T 19519. Manufacturers make them for 35 kV to 500 kV systems, both AC and DC. They’ve been used successfully—like in Germany’s 245 kV network, running since 1967, and China’s big 500 kV setups. Field studies always find failure rates under 0.5%.

Future Outlook

Scientists are developing new silicone rubber, with nano-fillers to better resist electrical tracking and erosion. They’re also changing FRP core materials to stop hydrolysis. These improvements aim to let the insulators work in ultra-high-voltage (UHV) systems and grids in the harshest climates.

Summary

Composite tension insulators have great mechanical strength and handle pollution well. Light and low-maintenance, they help build more efficient power networks. Now widely used in key strain applications—spots once dominated by porcelain—they’ve proven reliable worldwide for decades. Material science keeps making them better, too.