Composite Type Insulators: Enhancing Electrical Grid Reliability

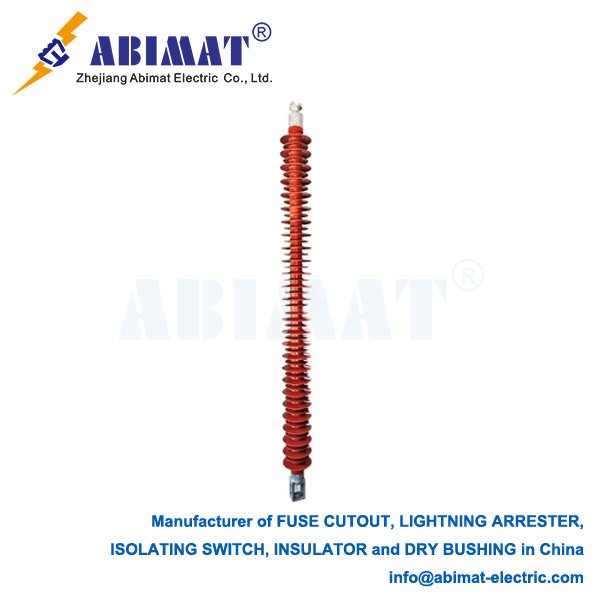

Composite insulators, also called polymer or non-ceramic insulators (NCIs), are a big step forward in high-voltage electrical insulation. They have two main parts. One is a strong fiberglass-reinforced polymer (FRP) core rod that holds weight. The other is an outer cover with polymeric weather sheds. These sheds are usually made from silicone rubber (SIR), ethylene propylene diene monomer (EPDM), or cycloaliphatic epoxy (CEP).

The FRP core is key here. It has great tensile strength. That means it can handle mechanical loads—like the weight of conductors, wind, and ice. It also has high dielectric strength. Unlike brittle materials, it doesn’t break easily. And it’s much lighter—about 80-90% lighter than similar porcelain or glass insulators. This light weight makes it more durable and easier to install.

The outer cover, mostly made of silicone rubber, has important features too. Silicone rubber naturally keeps water away. That stops a uniform conductive water film from forming on the surface. Even after pollution, this water-repelling property often comes back. It can even transfer to pollutants. This is a big deal. It cuts down on leakage currents a lot. It also stops pollution flashover—a common problem for ceramic insulators in dirty or coastal areas.

Being lightweight helps in other ways. It makes handling, transporting, and installing the insulators simpler. That lowers costs for labor and structural support. Composites are tough against impacts and vandalism too. Unlike brittle ceramics, they don’t shatter if shot or hit. This makes the power grid more resilient.

They work well in polluted places. The water-repelling feature, along with good leakage distance designs, lets them operate reliably in heavy industrial areas, deserts, or coastal regions. Good manufacturing is important here. It ensures a tight seal between the core and the cover. That keeps moisture out and prevents core corrosion—something that could make them fail.

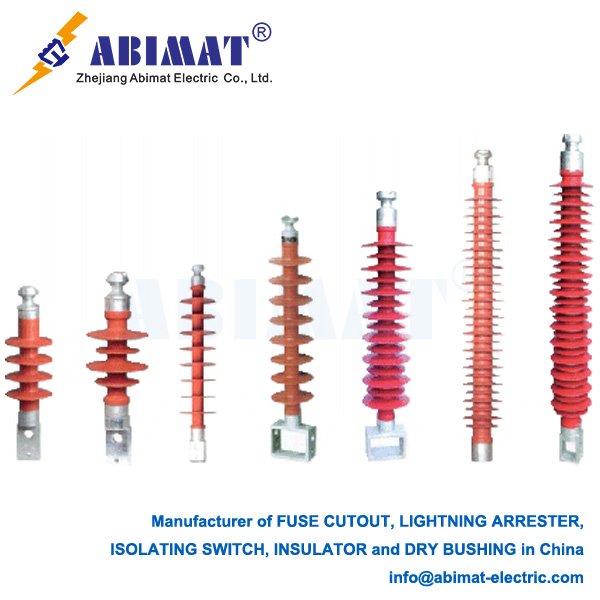

Composite insulators are now used all over the world in electrical networks. They’re in suspension strings for overhead transmission and distribution lines. They’re in line post setups in distribution systems. They’re used as station post insulators in substations. They insulate apparatus like circuit breakers and transformers. They’re in dead-end and tension applications. And they’re part of high-voltage direct current (HVDC) systems.

But there are things to watch for with their long-term performance. Core brittle fracture is one. If moisture gets through a bad end-seal, it can cause acid to break down the glass fibers in the FRP core. To stop this, manufacturers need strict quality control.

Tracking and erosion can happen too. If the insulators are under electrical stress for a long time, and with environmental factors, the surface of the cover might degrade. But new silicone rubber formulas are much better at resisting this.

Polymer covers have UV stabilizers. Silicone rubber, in particular, holds up well against weathering from UV rays. Sometimes, animals can be a problem. In certain designs or locations, steps need to be taken to stop damage from birds or other wildlife.

Research is ongoing to improve the materials. Scientists are looking at nano-filled silicones. These could make the insulators more resistant to erosion and better at handling heat. They’re also working on better ways to check the insulators’ condition—like analyzing leakage currents or detecting acoustic emissions. There are designs being optimized for ultra-high voltage (UHV) systems and very harsh environments.

Abimat composite type insulators have changed electrical insulation. They work better in polluted conditions. They’re strong mechanically, light, and hard to vandalize. All this means big benefits—both operational and economic—compared to traditional ceramic insulators. Materials, manufacturing, and design keep getting better. This ensures they’ll be key parts of building reliable, efficient, and modern electrical infrastructure. They’re especially useful in tough operating conditions. To make them last as long as possible, keeping strict quality standards and understanding how they age over time is crucial.