Cut-Out Fuse Links: An Essential Component for Overhead Line Protection

Cut-out fuse links—people often call them drop-out fuses—are important overcurrent protection devices. We use them a lot in medium-voltage overhead distribution networks. They help isolate faulty parts cheaply and reliably, which makes the electrical supply safer and more steady.

Construction and Key Components

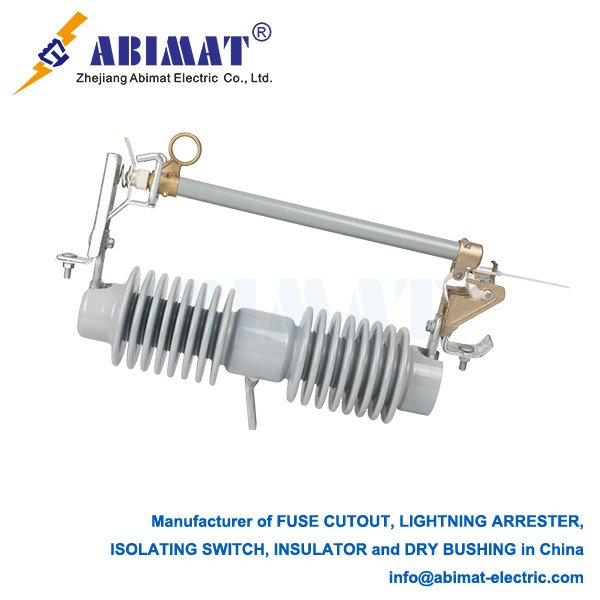

A typical cut-out fuse setup has three main parts: a waterproof base, a fuse carrier (that’s the holder), and the fuse link itself.

The base is made of insulating material—things like porcelain or polymer. It holds the whole setup together and has the fixed contacts inside.

The fuse carrier is the part you can take out. It holds the fuse link, and it’s designed to pivot and “drop out” when the device works—you can see this happen clearly.

The fuse link is a special element that’s set to work just right. It carries the load current normally, but it melts when there’s a fault.

Operating Principle

The device works on a simple electromechanical idea. When everything’s normal—when the load current is steady—the fuse link keeps the carrier tight in the closed position. This keeps the circuit connected.

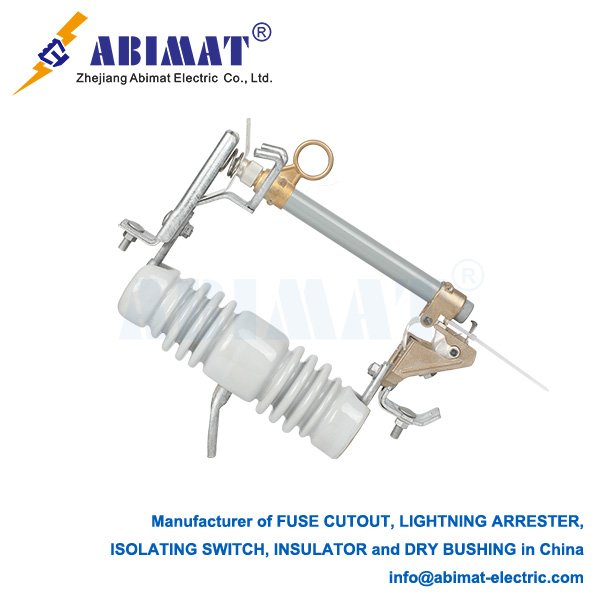

If there’s a short-circuit or a bad overload, the high current from that melts the fuse element fast. When this happens, an arc starts inside the carrier. Most fuse carriers have material inside to put out arcs—like boric acid or a sand-like stuff. This material makes gases that put out the arc quickly.

At the same time, the melting fuse element does two things: it either releases a spring-loaded part or takes away the tension that held the carrier in place. Once the carrier is free, it pivots down because of gravity. It hangs open after that, and this creates a clear air break you can see. This tells you the device has worked, and it also isolates the faulty circuit.

Primary Applications and Advantages

We mainly use cut-out fuse links to protect three kinds of equipment:

First, they protect distribution transformers that are mounted on top of utility poles.

They also protect tap lines and branches of overhead feeders.

And they protect capacitor banks and other sectionalizing points too.

They have three big advantages:

One, the dropped carrier shows clearly that the device has operated. This helps us find faults fast, so we don’t waste time checking.

Two, they’re a good deal—cheap but reliable for overcurrent protection. You don’t need to spend a lot to get good performance.

Three, they’re simple to use. They have strong parts, and not many moving pieces. So they last a long time, and you won’t struggle to operate them.

All in all, abimat cut-out fuse links are still basic and necessary protection devices in overhead distribution systems. They balance performance, safety, and cost well—there’s no better choice for this kind of job.