Disconnect Switches: Critical Safety Infrastructure in Substations

Disconnect switches (isolators) serve as indispensable components within electrical substations, providing essential safety isolation and operational flexibility. Unlike circuit breakers, these devices are not designed to interrupt load or fault currents. Their fundamental purpose is to establish a visible, physical air gap in de-energized circuits, ensuring safe equipment isolation for maintenance, testing, or system reconfiguration.

Primary Functions

I. Safety Assurance: Creates unambiguous isolation points for work on transformers, circuit breakers, or bus sections. The visible gap verifies de-energization before grounding equipment.

II. System Configuration: Enables power flow management by:

– Isolating feeders or bus sections

– Transferring loads between busbars

– Bypassing equipment

– Connecting/disconnecting transmission lines

III. Equipment De-energization: Safely isolates downstream equipment after circuit breaker operation.

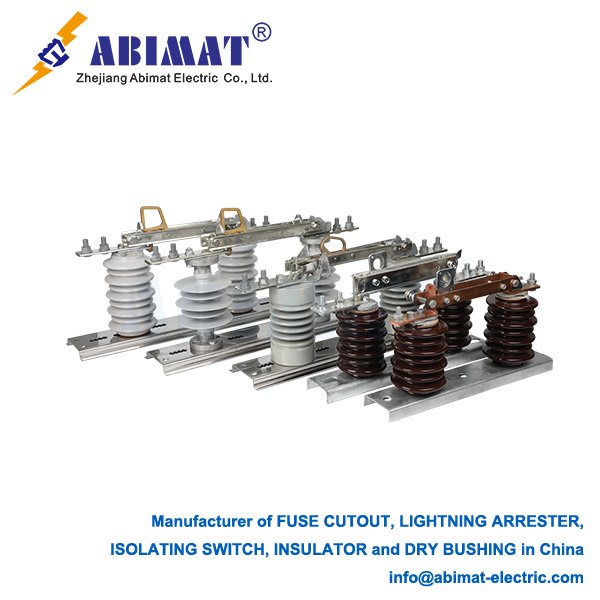

Common Substation Types

– Vertical-Break (66kV+): Rotating blades create vertical air gaps; standard for high-voltage outdoor installations.

– Center-Break: Horizontally rotating blades; typical for lower-voltage applications.

– Double-Break: Semaphore-style blades creating two series gaps; enhanced dielectric strength.

– Pantograph: Scissor mechanism for space-constrained bus connections.

– In-Line: May incorporate limited load-breaking capability or fuse integration.

Critical Design Parameters

Selection requires rigorous evaluation of:

– Electrical Ratings: Voltage class, continuous current, short-time withstand (kA/s), peak withstand current

– Dielectric Performance: Power frequency/impulse withstand voltage across open gap

– Environmental Resilience: Creepage distance (IEC 60815 pollution levels), ice/wind loading

– Mechanical Endurance: Minimum 1,000 operation cycles

– Actuation: Manual (lever/crank) or motorized operation for remote control

Operational Imperatives

– Visual Verification: Field personnel must physically confirm open-gap position before accessing equipment.

– Interlocking Systems: Prevent hazardous operations through:

– Mechanical key transfers blocking switch operation under load

– Electrical interlocks preventing closure on grounded circuits

– SCADA-controlled sequencing for automated substations

– Arc Management: Engineered to safely interrupt capacitive currents (e.g., unloaded bus charging current) using blow-open hooks or arc horns.

– Integrated Grounding: Paired with earthing switches for safe discharge of isolated sections.

Substation Applications

– Transformer/reactor isolation

– Circuit breaker maintenance bypass

– Busbar sectionalization

– Feeder connection/disconnection

– Test point establishment

Compliance and Maintenance

Governed by IEC 62271-102/ANSI C37.32 standards covering design, testing, and commissioning. Critical maintenance includes:

– Infrared scanning for contact overheating

– Visual inspection of blade alignment/contact erosion

– Lubrication of rotating mechanisms

– Interlock function verification

– Pollution monitoring in coastal/industrial areas

Conclusion

Abimat Disconnect switches form the backbone of substation safety protocols. Their ability to establish reliable visible isolation enables critical maintenance, protects personnel, and facilitates system reconfiguration. Proper selection based on electrical/mechanical requirements, integration of failsafe interlocks, and disciplined maintenance directly impact substation reliability. As power networks evolve, these fundamental devices remain vital for secure, resilient grid operations—where engineered safety solutions prevent human error and ensure operational continuity.