Drop-Out Fuse in Transformer Protection

The drop-out fuse—some people call it an expulsion fuse—is a basic overcurrent protection device. It’s widely used in overhead power distribution networks. Its main job is to protect distribution transformers, capacitor banks, and branch lines. It’s a cheap way to get both a fuse and a disconnecting switch in one. It protects the circuit, and it also creates a visible break in the line when you use it.

How It Works and What It’s Made Of

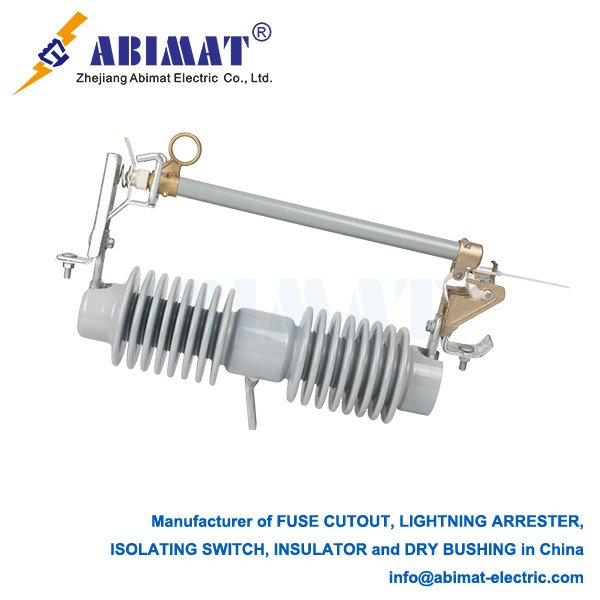

The main part of the fuse has a fuse link inside a fuse tube. The tube is usually made of an insulating material that can stop electric arcs—things like fiberglass or phenolic resin work well. It’s mounted at an angle on moving contacts, and these contacts sit in a strong insulating frame.

Under normal load conditions, the fuse link holds the tube in the “up” or closed position. This keeps the circuit connected and working properly.

Problems start when there’s a long-lasting overcurrent or a short-circuit fault. These issues make the fuse link melt. Once the link melts, an internal arc starts. This arc turns the tube’s lining into vapor, creating de-ionizing gases. These gases push the arc out forcefully, stopping the current.

When the current stops, the upper hinge of the tube—now free from the melted link—swings open. Gravity pulls the tube down, and it pivots into a fully open, hanging position. This “drop-out” is easy to see. It tells you the device has worked, and it isolates the part of the circuit with the fault.

Key Parts and Features

- Fuse Element: This is a calibrated wire or strip. It melts when the current reaches a certain level, and it follows a set timing rule.

- Fuse Tube: It acts as a chamber to put out arcs. It holds the gases created when the current is stopped.

- Contacts and Hinges: These parts let the tube pivot and drop open reliably every time it needs to.

- Mounting Bracket: It keeps the whole assembly insulated from the grounded pole or crossarm.

One critical design feature is that the device doesn’t limit current. It can’t stop the peak current that flows during a fault. Its ability to stop current follows industry standards—like ANSI/IEEE C37.41. You have to choose the right one based on the maximum fault current the system can have.

Where It’s Used and Why It Matters

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo

For transformer protection, the drop-out fuse is usually put on the primary (high-voltage) side. It protects the transformer from harmful external faults and internal problems. By isolating the transformer when there’s an issue, it stops the fault from disrupting more of the power network.

Its simple, tough design makes it perfect for overhead lines in rural and suburban areas. Choosing the right ampere rating for the fuse link is very important. The link must let the normal inrush current of the transformer pass without melting. But when there’s a fault current, it needs to melt quickly to clear the problem.

To sum up, the drop-out fuse is still a vital, reliable part in medium-voltage distribution systems. It does two jobs well: it protects equipment, and it works as a visible disconnect. This makes it a practical and cheap solution for keeping transformers safe and improving the overall reliability of the power grid.