Drop-Out Fuse Link: Operation and Application

Drop-Out Fuse Link: Operation and Application

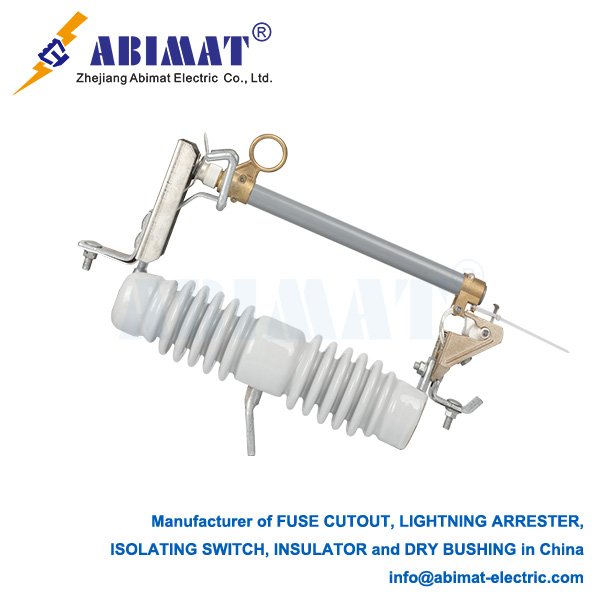

A drop-out fuse link, also called an expulsion-type distribution fuse cutout, is a key overcurrent protection device. It is widely used on overhead power distribution systems, usually for voltages between 2.4 kV and 38 kV. This device has two important jobs: it works as a fuse to stop fault currents, and it acts as a visible disconnect switch once used.

Construction and Operating Principle

The device has three main parts: an insulator made of molded epoxy or polymer, a fuse holder (the “door” or “tube”) that holds a replaceable fuse link, and a hinged contact part mounted on a bracket. Under normal conditions, the fuse holder stays tight in the closed (upright) position. It keeps the circuit complete through the fusible element inside.

When there is a long-lasting overcurrent or a fault, the fusible element inside the holder melts (clears). This melting relieves the tension on the fuse holder. The holder then swings down on its hinge because of gravity. It drops to a fully open, hanging position. This “drop-out” movement creates a clear, visible gap in the circuit. It tells people the device has worked and points out the faulty section.

Key Types and Characteristics

There are two main types of fuse link technologies.

1. Expulsion-Type: This is the most common type. The fuse link is placed inside a fiberglass or similar tube. When the device stops the current, the electric arc produces gases from the tube lining. These gases create a blast that reduces ionization and puts out the arc. You can hear a sound when it works.

2. Solid-Material or Current-Limiting Type: The fuse link is set in solid granular material, such as quartz sand. When the fuse link melts, the sand puts out the arc very quickly. This greatly limits the maximum current and energy that passes through.

Applications and Advantages

Drop-out fuse links are mainly used to protect distribution transformers, capacitor banks, and tapped feeders. Their main benefits are as follows.

Clear Indication: The dropped holder gives a clear visual sign of a fault from far away. You can’t miss it.

Isolation: It provides physical separation. This makes work safer for maintenance teams.

Cost-Effectiveness: They are a reliable and cheap solution for overcurrent protection in overhead networks.

Easy Restoration: After finding and fixing the fault, you can restart the line easily. Just replace the fuse link and close the holder again.

Selection and Coordination

To choose the right fuse, you need to match its voltage and current ratings to the power system. The time-current characteristic (TCC) curve of the fuse must work well with the protective devices upstream and downstream. This ensures the fuse works selectively, reducing the area affected by power outages. Following standards like IEEE C37.41 is important for reliable operation.

In short, abimat the drop-out fuse link is still an important, field-tested component for protecting overhead distribution equipment. It is simple to use. It stops faults reliably and has a built-in visible disconnect feature. These qualities make it essential for protecting power systems and keeping operations safe.