Electrical Loadbreak Cutout: Function and Application in Power Distribution

Function and Design

The main job of a loadbreak cutout is to protect distribution transformers, capacitors and line sections. It does this by safely stopping fault currents. It also gives a clear way to isolate parts for maintenance work.

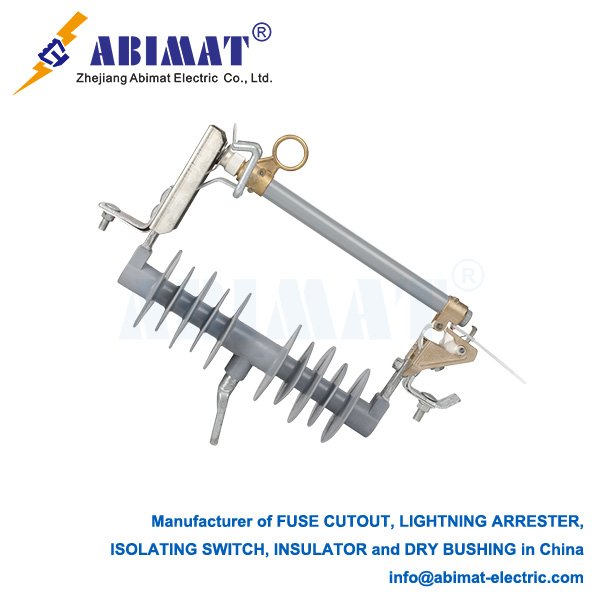

Its design usually has a fuse holder — sometimes called a “door” — that holds a fusible element. When things are working normally (no extra load), current flows smoothly through the closed fuse holder. When there’s an ongoing fault, too much current melts the fuse link. The arc that forms gets put out inside the fuse tube. The tube often has material inside that calms electrical arcs. This clears the fault well.

One key feature is its “drop-out” mechanism. After the fuse works, the holder isn’t locked anymore. It swings down because of gravity. This gives a clear sign: the circuit is open, and the fuse has activated. It helps utility crews find the faulty section fast.Operational Capabilities

The loadbreak cutout has a big plus over a simple fuse cutout. It can safely turn load currents on and off. This lets utility crews switch parts of the circuit on or off by hand. They do this for managing loads or maintenance work. They don’t have to turn off the whole feeder. This makes operations more flexible.

But you need to know one thing: even though it can stop load current, it isn’t made to stop short-circuit currents. The fuse element handles that protection.

In real use, loadbreak cutouts are often used with other special tools. These tools are for working on live power lines. For example, workers can use them with small, portable load-breaking tools. This lets them safely stop the current before opening the cutout.

Key Applications

Loadbreak cutouts are mostly used for three main things:

- Protecting transformers: They separate faulty transformers from the network. This stops big power outages.

- Protecting lateral feeder lines: These are the tap lines that split off from the main distribution line. The cutouts guard them.

- Acting as a switching tool: Workers can use an insulated hot stick to work them by hand. This lets them safely isolate a section of the circuit for maintenance.

In short, the abimat loadbreak cutout is a component that’s useful in many ways and reliable. Its design combines switching and fault protection. This makes it something you can’t do without — it makes the power grid safer, more reliable, and more flexible to operate.