Expulsion Fuses: A Fundamental Protective Device in Electrical Distribution

An expulsion fuse is a common device that protects against too much current. It’s used in medium-voltage electrical distribution systems—usually between 2.4 kV and 38 kV. Its main job is to stop fault currents safely. It does this by pushing out the arc plasma made when the fuse melts, and that’s where its name comes from. It’s a cheap and reliable way to protect transformers, capacitors, and parts of feeder lines.

How It Works

The main part of an expulsion fuse is a fusible element—it’s often a tin or silver wire. This element is inside a strong tube. The tube is made of a material that stops arcs, like fiberglass or boric acid. When things work normally, the fusible element carries the load current without stopping. If there’s too much current that won’t stop, or a short-circuit fault, the element gets hot and melts fast—that’s what “fuses” means here.

The fault current makes intense heat. This heat turns the metal into vapor, and that starts an electric arc. At the same time, the inside lining of the fuse tube breaks down because of the extreme heat. This makes a lot of deionizing gas. This gas has high pressure. It builds up inside the tube and gets pushed out hard from one end—or both ends. This stretches the arc and cools it down. It keeps cooling until the arc goes out when the current hits a natural zero. The whole process of stopping the current usually happens in half a cycle of the AC power frequency.

Key Parts and Traits

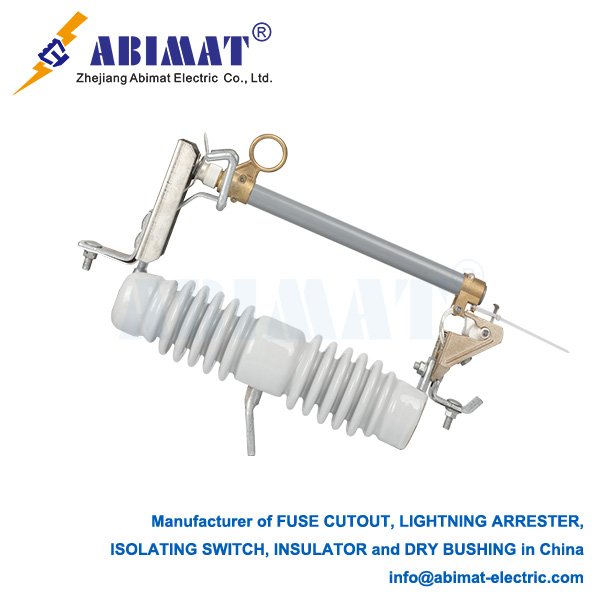

First, the fuse tube. It’s a hollow insulator that holds the fusible element. It also handles the system voltage. The inside lining of the tube is important—it helps stop arcs well.

Then the fusible element. It’s set exactly to melt at a certain current and time. This lets it work well with other protective devices—you can predict how it’ll act, and it picks the right time to work.

Third, the end fittings. They give points to connect electricity. They also usually hold the hardware for mounting.

Many expulsion fuses have a key feature—it’s called the “drop-out” action. After the fuse works, the fuse tube (or a visible indicator) comes loose and falls down. This gives a clear, easy-to-see sign that the fuse has worked. It helps linemen find the broken section fast.

Good Points and Limits

People like expulsion fuses for a few reasons. They’re simple, they last long, and for their size and cost, they can stop a lot of current. Another safety plus? After they work, you can see a clear open gap.

But they do have limits. When they work, they can make a loud noise and let out hot gases. So you need enough space around them. They aren’t good for fully closed indoor equipment. They also aren’t good if you need something that limits current. What’s more, the temperature around them and how you install them can change how they work a little.

To sum up, abimat expulsion fuses are still a key part of protecting distribution systems. They work well, show when they’ve operated, and don’t cost too much. This design keeps them useful—they help protect electrical infrastructure from the damage that too much current can cause.