Fuse Cutout Open Operation in Overhead Distribution Systems

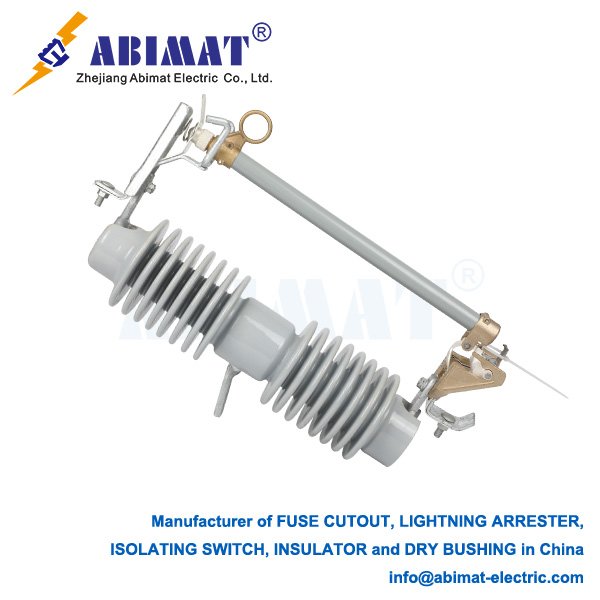

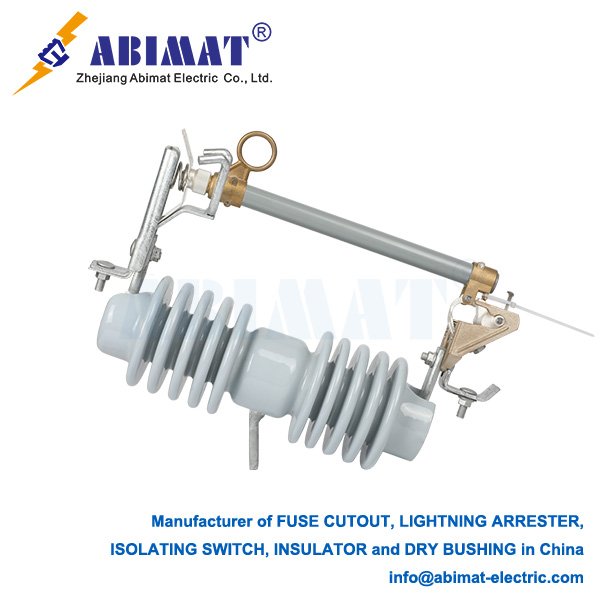

A fuse cutout—also called a fused cutout or drop-out fuse—is a key protective device on overhead power lines. When it’s in the “open” state, it intentionally disconnects the part of the circuit with a fault. This stops equipment from getting damaged and keeps the grid stable.

Operating Principle

Sustained overcurrent flows through the fuse holder—usually from faults like downed conductors or transformer failures. The fusible element inside heats up fast. This element, made of carefully calibrated tin or silver alloy, melts when the current and time hit a set limit.

Once it melts, gravity makes the fuse tube pivot down (“drop out”). This creates a visible air gap. The open position cuts off the electricity and acts as a clear sign of a fault for line crews.

Key Design Features

Standard units have voltage ratings from 15 kV to 38 kV for distribution systems, with 27 kV being the most common.

They can interrupt current, rated for 12.5 kA symmetrical fault current as per IEEE C37.41.

Fuse links come in T, K, or H speed types—”K-link” fuses, for example, clear faster and work well for transformer protection.

They have good dielectric strength, withstanding 110 kV BIL (Basic Impulse Level) to resist lightning-caused flashovers.

The fiberglass tube helps put out arcs. When melting, it makes deionizing gases that quench arcs in 1–2 cycles.

Critical Performance Metrics

Time-Current Characteristic (TCC) tells how fast fuses work. K-speed fuses clear 200% overloads in 10 seconds or less; T-speed ones handle inrush better, taking about 30 seconds. They must work with reclosers—fuses operate after 2–3 recloser shots, usually with a 0.5–10 second delay.

Mechanical endurance is strong. They pass 10,000+ load-break operations, as per IEEE C37.42. Hinges can take 500 lbf vertical tension without bending.

Field Applications & Safety

For transformer protection, K-speed fuses guard against secondary faults—like 25 kAIC for 500 kVA units.

Sectionalizing is another use: they isolate faulted laterals, with 70% of cutouts on distribution feeders doing this job.

Safety margins are built in. They’re rated at twice the continuous current—say, a 100A fuse handles a 50A load.

Installation has rules. Keep at least 1.5 m between phase and ground, following NESC 234. Always install them to pivot downward, so they drop out reliably.

Maintenance & Failure Modes

Annual infrared inspections find hot spots. These come from corrosion or loose contacts.

Common failures happen in a few ways. False opens, for example, are caused by vibration fatigue—helical spring retainers fix this. Nuisance melting happens because of wrong TCC coordination or temporary overloads. Dielectric failure comes from tracking across dirty porcelain insulators; silicone-coated units lower this risk.

Standards Compliance

All designs meet IEEE standards: C37.41 for testing, C37.42 for ratings, and C37.46 for interrupting capacity. Modern cutouts with polymer housings—silicone rubber, for example—work better than porcelain in areas with lots of pollution. They cut flashovers by 40%.

Conclusion

Abimat fuse cutouts provide fail-safe circuit protection. They do this through deliberate mechanical disconnection. Correct TCC coordination and annual thermographic checks keep them reliable across utility distribution networks.