Hollow Insulators: Critical Components for High-Voltage Systems

Introduction

Hollow insulators are basic parts in many places. In Gas Insulated Switchgear (GIS), they make the grounded cases. They also keep different phases and sections insulated from each other. In dead tank circuit breakers, they hold the interrupter units and contain the insulating gas. For surge arresters, they hold the active parts inside. In instrument transformers (current and voltage types), they separate the primary conductor and act as the insulating cover. For bushings, they guide high-voltage conductors through grounded walls or tanks—like those on transformers, circuit breakers, and capacitors. In disconnectors and earthing switches, they support moving contacts and provide insulation. They are also used in Capacitor Voltage Transformers (CVTs).

Structure and Materials

Their core structure is what makes them different—it’s usually a cylinder. This core is sealed at both ends with metal plates or end parts. This creates a container that can hold insulating materials, like sulfur hexafluoride (SF6) or oil. Sometimes it just separates a conductor.

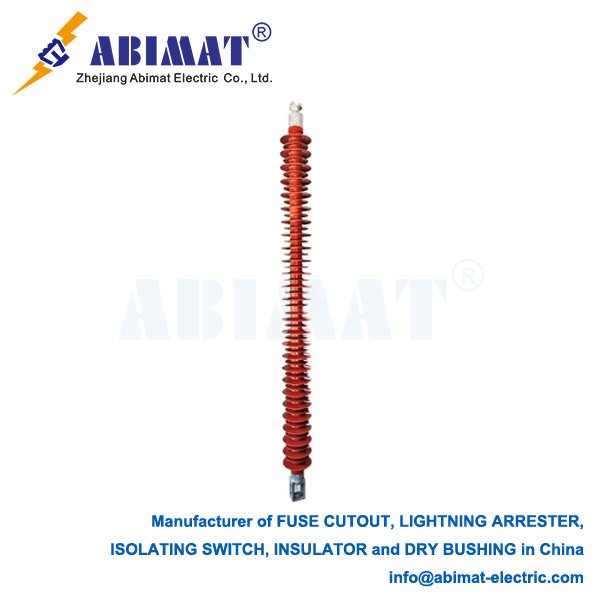

The outer shell gives the main electrical insulation. There are two main materials for this shell. One is composite, or polymer. It has a fiberglass-reinforced epoxy (FRP) tube for mechanical strength. Around this tube, there are silicone rubber covers and sheds. Silicone repels water well, works great in dirty conditions, is light, and resists impacts. This is the most common type used today. The other material is porcelain, or ceramic. It’s a traditional material that’s strong when pressed and stays stable for a long time. It needs a glaze to repel water, though. It’s heavier, easier to break, and doesn’t work as well in dirty conditions as composite insulators.

Key Functions and Advantages

For electricity, they provide the insulation needed. They keep the right distance between the high-voltage conductor inside and the grounded structure outside. This stops electrical flashes. They also work as strong structural parts. They support heavy components—things like circuit-breaker interrupters, disconnector contacts, transformers, capacitors, or busbars. Often, these parts have big cantilever loads. They form a sealed space too. This space holds insulating or arc-quenching materials (like SF6, oil, or air) at working pressures. This is very important for Gas Insulated Switchgear (GIS), dead tank circuit breakers, instrument transformers, and bushings. They also act as a barrier against the environment. They protect inner parts from outside dirt, like moisture, dust, and pollution. On the flip side, they keep inner materials safe inside.

Composite hollow insulators are getting more popular for good reasons. They are lighter—this makes them easier to handle and reduces loads on structures. They resist damage from vandalism and don’t shatter explosively. They work well in dirty and humid places because they repel water. And they usually need less maintenance.

Primary Applications

Hollow insulators are basic parts in many places. In Gas Insulated Switchgear (GIS), they make the grounded cases. They also keep different phases and sections insulated from each other. In dead tank circuit breakers, they hold the interrupter units and contain the insulating gas. For surge arresters, they hold the active parts inside. In instrument transformers (current and voltage types), they separate the primary conductor and act as the insulating cover. For bushings, they guide high-voltage conductors through grounded walls or tanks—like those on transformers, circuit breakers, and capacitors. In disconnectors and earthing switches, they support moving contacts and provide insulation. They are also used in Capacitor Voltage Transformers (CVTs).

Conclusion

The abimat hollow insulators are smart, multi-use parts. They are critical for safe, reliable, and smaller designs of modern high-voltage electrical equipment. More and more people are using composite technology. This has made their performance much better, especially in hard environments. It also brings benefits in weight, safety, and lifecycle costs. They can do three things at once: insulate electricity, give mechanical strength, and hold pressure. This makes them a must-have for uses from substations to transmission systems. Factories follow strict global rules (like IEC, IEEE, ANSI) when designing, testing, and making them. This ensures they are reliable.