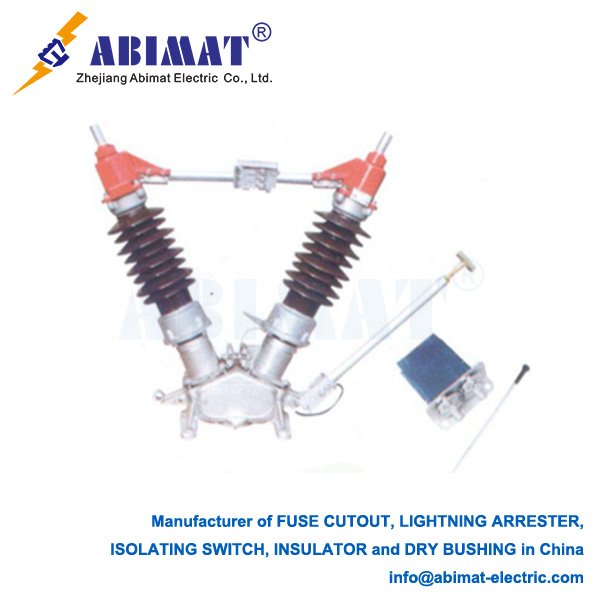

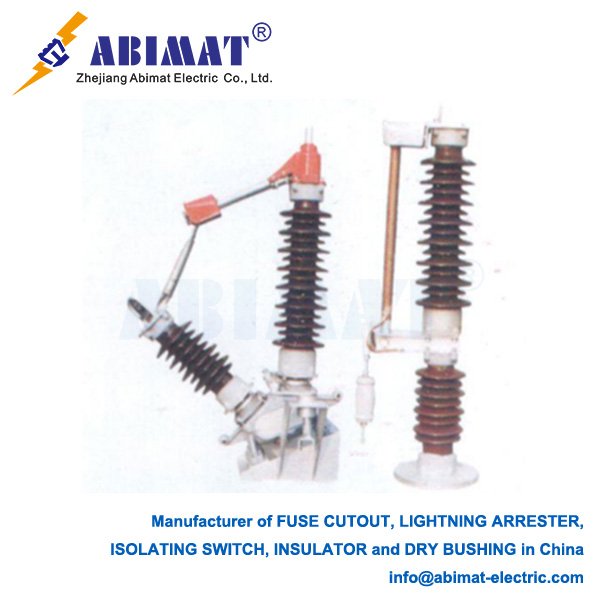

Load Break Disconnects: Purposeful Switching in Medium-Voltage Systems

A Load Break Disconnect (LBD) is an important piece of equipment in electrical distribution systems. It’s built to safely make and break load currents when the system is working normally. It has a clear job—filling the gap between what a simple isolator (disconnector) does and what a full-rated circuit breaker does

The main job of an LBD is to give a safe, easy-to-see way to isolate a circuit with no power. It can also stop rated load currents. This makes it different from two other devices:

An Isolator (Disconnector): This device is made to open a circuit only after something upstream (like a circuit breaker) stops the current. It gives a safe, easy-to-see air gap for maintenance work. But it can’t stop current itself.

A Circuit Breaker: This device can stop normal load currents. It can also safely stop large short-circuit (fault) currents.

An LBD doesn’t have the complicated parts that stop fault arcs. So it must always be used with upstream fuses or circuit breakers. These parts protect the system from faults.

When the contacts inside an LBD move apart while carrying load, an electric arc forms naturally. The LBD is built with special parts to put out this arc safely. This arc is usually held inside a sealed space. The space is filled with a dielectric material—like oil, air, or SF6 gas (which is most common in new designs).

The parts that control the arc (they usually use pistons or blowers) stretch the arc, cool it down, and remove its electric charge. They do this until the arc can’t keep going anymore. Then the current is stopped successfully. This lets workers safely turn off power to transformers, capacitors, cables, and other medium-voltage equipment. They do this during planned maintenance or when they need to reconfigure the system.

LBDs have three key features:

Rated Voltage – this is the voltage they’re made for (like 15 kV or 25 kV)

Rated Continuous Current – this is the current they can carry nonstop

Rated Load Break Current – this is the exact current level they’re approved to stop

People use LBDs in a few common ways:

They isolate transformers or capacitor banks from the live electrical network

They split overhead distribution lines into sections. This helps isolate parts that have faults

They work as the switching part in pad-mounted switchgear and ring main units

The abimat Load Break Disconnect is a special, low-cost way to handle normal switching work in medium-voltage networks. Engineers need to understand what it can do and what it can’t. One important thing: it’s not made to stop faults. If they know this, they can use LBDs well. This makes the network more flexible to operate and safer.