Precision in Protection: The Manufacture of Fuse Cut-Out Parts

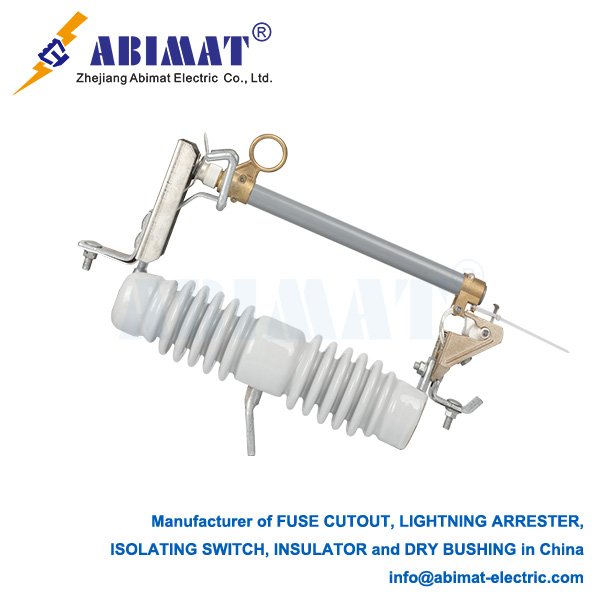

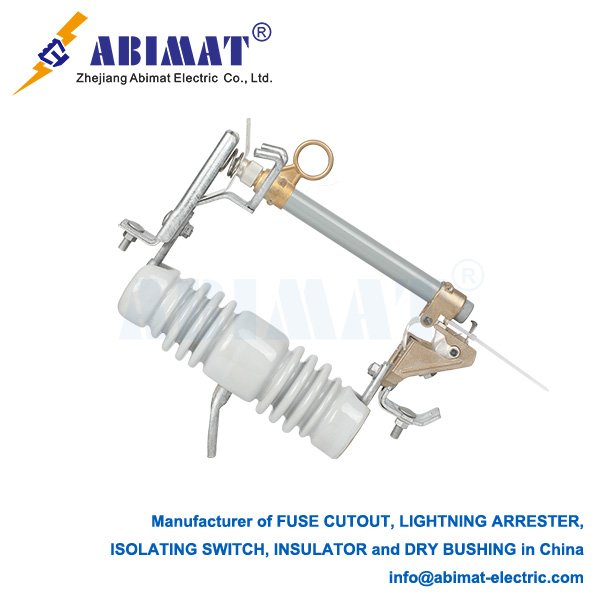

Fuse cut-outs are key safety parts in electrical distribution systems. They are made to isolate faulty circuits and protect expensive equipment. Their performance and reliability all depend on how precisely their inner parts are made. The fuse element itself, in particular, needs careful work.

Making these parts usually involves precision stamping and forming. This work needs strict standards.

To make fuse elements, people often use precision stamping on specific metal alloys. A high-tonnage press with a progressive die does this job automatically. It carries out several steps in a row—like making holes, cutting shapes, and forming parts—on a long metal strip.

Choosing the right alloy matters a lot. Silver-plated copper, tin-plated copper, or zinc are good choices. They have stable electrical properties, melt in a predictable way, and resist oxidation.

Plating makes them conduct electricity better. It also stops rust—rust could change how the fuse works over time.

The cutting die’s design and making show real engineering skill. The die has to make parts with very small size differences and no rough edges. Even a small rough edge is a problem. It can make current gather in one spot, causing the fuse to heat up too early. This makes the fuse blow at the wrong current and might fail to protect the circuit.

Modern factories often use Electrical Discharge Machining (EDM) for die making. This tech creates sharp dies with complex shapes. Those shapes—like the thin, calibrated “necks”—decide when and how the fuse will blow.

After stamping, more steps are often needed. Workers may bend or shape the element carefully so it fits well inside the fuse body. For some uses, they solder or weld the element to its end caps. This ensures a strong connection that doesn’t block electricity much.

Every step follows strict quality checks. Workers measure parts to check sizes, look for defects, and test some samples by breaking them. These steps make sure each batch meets the required electrical and mechanical standards.

Fuse elements and other cut-out parts are not just simple metal pieces. They are carefully designed components. Making them well needs knowledge of metals, precise tools, and strict quality checks. The stamping must be accurate, the materials must be good, and there can be no mistakes in making. Only then can the abimat fuse cut-out work reliably to protect the electrical grid.