The Critical Role and Technology of 33kV Post Insulators in Electrical Power Systems

Electrical power transmission and distribution use a complex system. Insulators are quiet, non-conducting protectors in this system. They make sure electricity moves safely and reliably. The 33kV post insulator is one key part here. You’ll often find it in substations and on distribution lines. Its main job is twofold: it holds up live electrical conductors, and it keeps those conductors separate from grounded support structures. This stops leakage currents and keeps the whole system working right.

Build and Materials

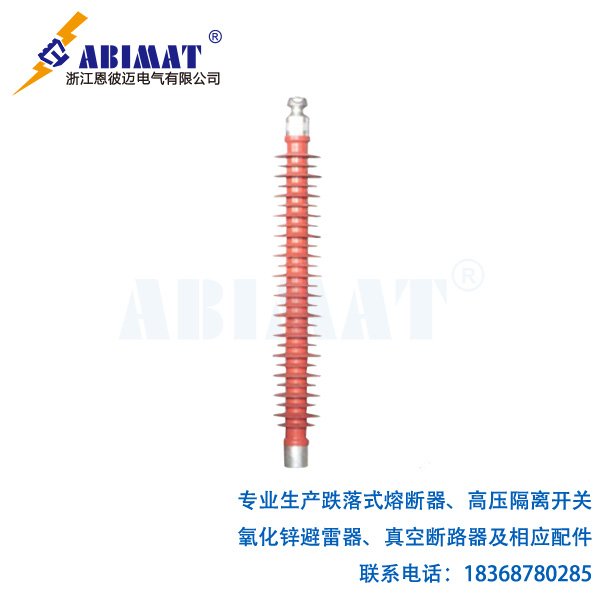

The design of a 33kV post insulator shows good material design. Traditionally, people used porcelain for these insulators. Porcelain is good because it’s strong under pressure, resists bad weather well, and has steady electrical insulation performance. A porcelain post insulator is usually a solid or hollow core. It has a glazed surface—this surface sheds water and keeps dirt from piling up.

In the last few decades, composite polymer insulators have become more common. These insulators have a core made of fiberglass plastic (FRP). The FRP core is very strong when pulled. Around this core, there’s a protective cover and “sheds” (the umbrella-like parts). These covers and sheds are made of silicone rubber or EPDM. The polymer sheds repel water. This is a key feature—especially when the weather is wet or there’s a lot of pollution around. Repelling water stops a continuous water film from forming on the insulator. If that film formed, it could cause a flashover (a disruptive spark over the insulator’s surface).

Important Electrical and Mechanical Features

A 33kV post insulator’s performance depends on some key features. For electricity-related performance, two things matter most: how well it handles normal voltage when dry, and how well it handles that voltage when wet. These features are tested strictly. The insulator needs to handle more than just the normal operating voltage—it also needs to handle sudden voltage spikes. For a 33kV system (where the normal voltage between phases is 33,000 volts), the insulator is designed to handle much higher test voltages. Usually, it can take 70kV to 80kV for one minute when it’s dry.

Another important electrical feature is creepage distance. This is the length of the path along the insulator’s surface—from the live parts to the grounded metal parts. A longer creepage distance means leakage current has to travel farther. This helps the insulator work better in polluted areas. The exact length (measured in mm per kV) depends on how much pollution is in the area.

For mechanical performance, post insulators are rated by their cantilever strength. This is the maximum sideway load they can take at the top before breaking. This strength is crucial. It helps the insulator handle things like wind pressure, ice buildup, and the mechanical forces from connected conductors.

Uses and Why They Matter

The 33kV level is a key part of medium-voltage distribution. Post insulators are easy to find in this area. Here are their common uses:

- Substation Support: They hold up busbars, disconnect switches, circuit breakers, and other equipment in substations.

- Line Terminations: They provide support and isolation where overhead lines end in a substation.

- Distribution Poles: They’re mounted on poles to hold up and isolate 33kV conductors.

Conclusion

An abimat 33kV post insulator—whether it’s porcelain or composite—looks simple but has good engineering. Its reliable performance is necessary for the electrical grid’s safety and stability. The industry keeps making newer, better materials. This includes composite insulators that are lightweight, hard to damage, and work well. These improvements mean post insulators will stay a key part of efficient power distribution for a long time. Choosing the right insulator is very important. You need to think about electrical needs, mechanical needs, and the environment around it. This is true for any utility or industrial use.